Understanding the Evolution of Flight Case Materials

The transportation and entertainment industries have long relied on sturdy flight cases to protect valuable equipment during transit. While plywood has been the traditional material of choice, pp bubble guard board is emerging as a revolutionary alternative that's reshaping how we think about protective packaging. This innovative material combines durability with remarkable lightweight properties, making it increasingly popular among professionals who need reliable equipment protection without the burden of excessive weight.

Core Benefits of PP Bubble Guard Board Technology

Superior Weight Reduction Capabilities

The most striking advantage of pp bubble guard board lies in its exceptional weight-to-strength ratio. Compared to traditional plywood, this innovative material can reduce the overall weight of flight cases by up to 60%. This significant weight reduction translates into substantial cost savings in shipping and handling, while also making cases easier to maneuver during load-in and load-out operations.

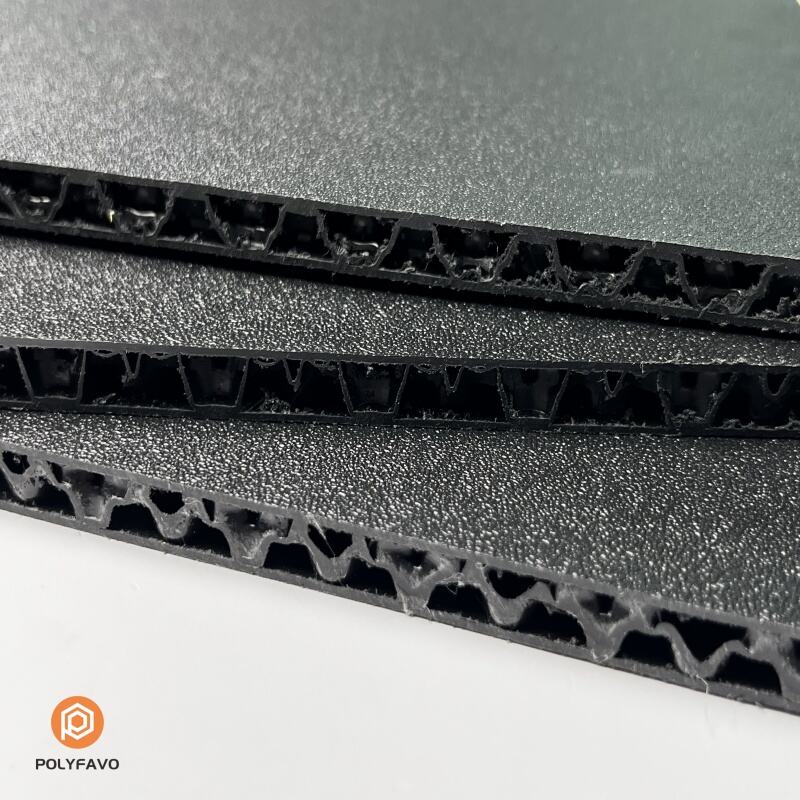

The unique construction of pp bubble guard board, featuring a honeycomb-like internal structure, contributes to its lightweight nature without compromising structural integrity. This ingenious design allows the material to maintain rigidity while eliminating unnecessary mass, making it an ideal choice for applications where weight considerations are paramount.

Enhanced Durability and Protection

Despite its lighter weight, pp bubble guard board demonstrates remarkable durability in protecting valuable equipment. The material's polypropylene composition offers excellent impact resistance and shock absorption properties. The internal bubble structure acts as a cushioning system, dispersing impact forces across a wider area and preventing damage to the contents within.

Additionally, pp bubble guard board boasts superior weather resistance compared to plywood. It's naturally water-resistant and doesn't require additional waterproofing treatments, eliminating the risk of warping, rotting, or delamination that often affects wooden materials when exposed to moisture.

Environmental and Economic Implications

Sustainable Manufacturing Process

The production of pp bubble guard board aligns with modern sustainability goals. Unlike plywood, which requires harvesting trees and extensive processing, pp bubble guard board can be manufactured using recycled materials and requires less energy during production. The material is also fully recyclable at the end of its life cycle, contributing to a more circular economy in the packaging industry.

The reduced carbon footprint extends beyond manufacturing - the lighter weight means lower fuel consumption during transportation, further decreasing the environmental impact throughout the product's lifecycle.

Cost-Effectiveness Over Time

While the initial investment in pp bubble guard board flight cases might be comparable to plywood alternatives, the long-term cost benefits are substantial. The material's durability means less frequent replacement is needed, and its lightweight nature results in ongoing savings in shipping and handling costs. These advantages make it an economically sound choice for businesses looking to optimize their operational expenses.

The material's resistance to environmental factors also reduces maintenance costs, as it doesn't require regular treatments or repairs that wooden cases often need to maintain their protective properties.

Design Flexibility and Customization Options

Versatile Manufacturing Capabilities

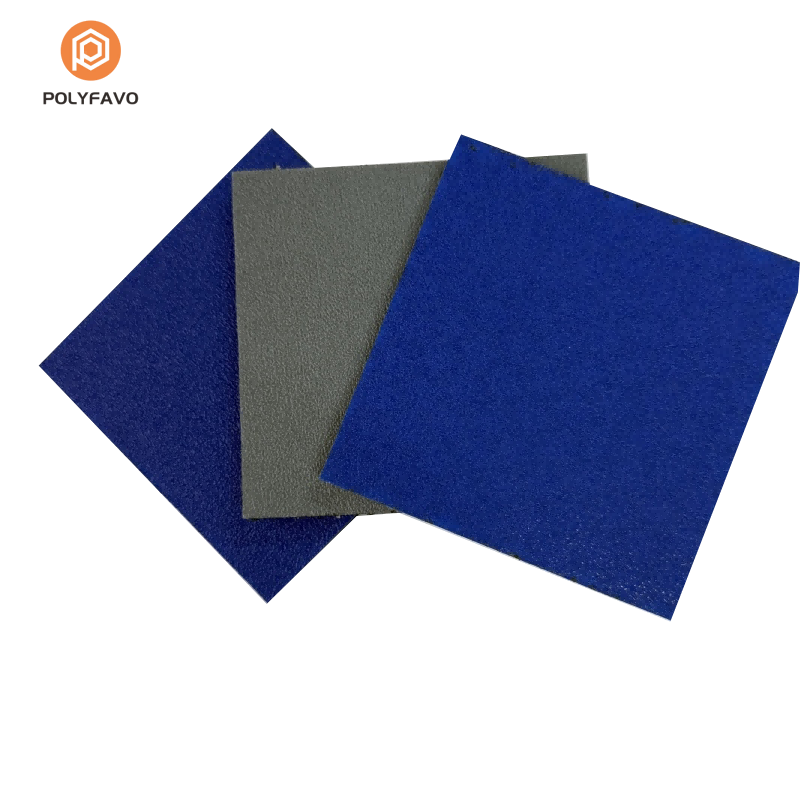

PP bubble guard board offers unprecedented design flexibility that traditional plywood cannot match. The material can be easily cut, folded, and formed into complex shapes without compromising its structural integrity. This versatility allows manufacturers to create custom flight cases that perfectly match specific equipment dimensions and protection requirements.

The material's uniform composition also ensures consistent quality across all surfaces, eliminating the natural variations and potential weak points often found in wooden materials. This uniformity contributes to more reliable and predictable performance in protecting valuable equipment.

Advanced Integration Features

Modern pp bubble guard board can be manufactured with integrated features that enhance functionality. These might include built-in channels for cable management, reinforced mounting points for hardware, or specialized zones for additional impact protection. Such features can be incorporated during the manufacturing process, resulting in a more streamlined and efficient final product.

The material's smooth surface also provides an excellent substrate for branding and customization options, allowing companies to maintain professional appearance while benefiting from superior protection.

Performance in Extreme Conditions

Temperature Resistance

PP bubble guard board maintains its structural integrity across a wide temperature range, making it suitable for various transportation and storage conditions. Unlike plywood, which can become brittle in extreme cold or warp in high heat, pp bubble guard board remains stable and continues to provide reliable protection regardless of environmental conditions.

This temperature stability is particularly valuable for equipment that needs to be transported through different climate zones or stored in non-climate-controlled environments. The material's consistent performance helps ensure valuable contents remain protected under varying conditions.

Impact and Vibration Management

The unique structure of pp bubble guard board provides superior vibration dampening compared to solid materials like plywood. The internal air chambers act as natural shock absorbers, reducing the transmission of potentially damaging forces to the protected equipment. This characteristic is especially valuable for sensitive electronic equipment or delicate instruments that require careful handling.

The material's ability to absorb and distribute impact forces makes it particularly well-suited for applications where equipment might be subjected to rough handling or challenging transportation conditions.

Frequently Asked Questions

How does pp bubble guard board compare to plywood in terms of lifespan?

PP bubble guard board typically offers a longer lifespan than plywood when used in flight cases. While plywood may begin to show signs of wear, delamination, or water damage within a few years, pp bubble guard board can maintain its protective properties for 5-10 years or more with proper use and care.

Can pp bubble guard board flight cases handle the same load capacity as plywood?

Yes, when properly designed, pp bubble guard board flight cases can match or exceed the load-bearing capacity of plywood cases. The material's structural design allows for excellent compression strength while maintaining its lightweight characteristics.

Is pp bubble guard board more expensive than traditional plywood?

While the initial cost of pp bubble guard board might be slightly higher than plywood, the total cost of ownership is often lower when considering factors such as reduced shipping costs, longer lifespan, and minimal maintenance requirements. The material's durability and performance characteristics typically justify the investment over time.

What maintenance is required for pp bubble guard board flight cases?

PP bubble guard board requires minimal maintenance compared to plywood. Regular cleaning with mild soap and water is usually sufficient. The material doesn't need waterproofing treatments, paint, or protective coatings, making it a low-maintenance solution for flight case construction.