The Evolution of E-commerce Packaging Solutions

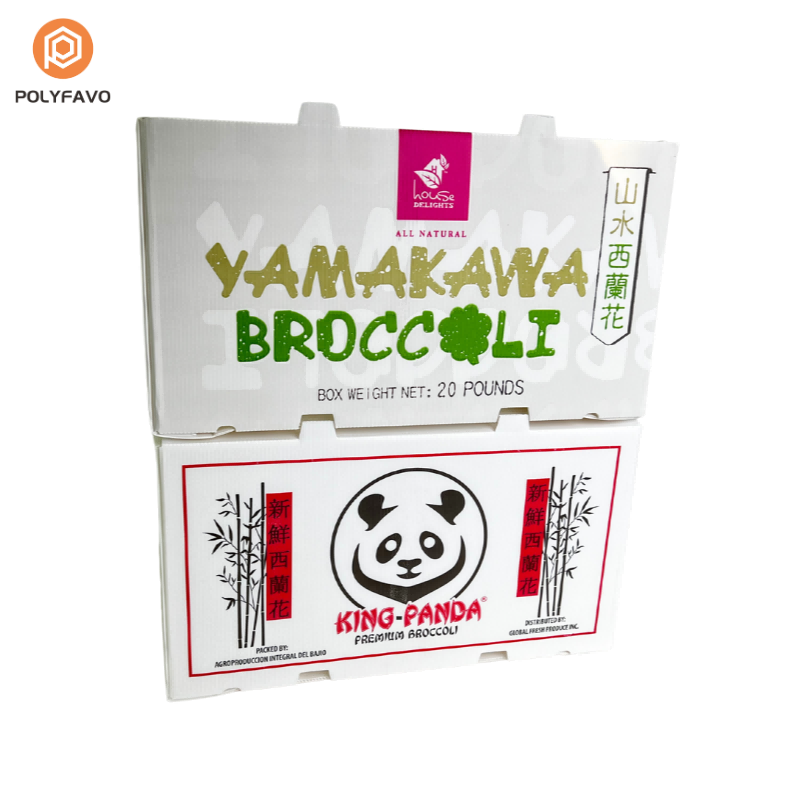

The e-commerce industry continues to reshape how businesses approach packaging and shipping solutions. As online retail grows exponentially, the demand for lighter, more efficient packaging materials has become paramount. Corrugated plastic packaging has emerged as a revolutionary solution that addresses multiple challenges faced by modern e-commerce shippers, particularly in reducing overall package weight while maintaining superior protection.

Traditional packaging materials often result in excessive shipping costs and environmental concerns. The introduction of corrugated plastic packaging represents a significant advancement in shipping technology, offering a perfect balance between durability and weight reduction. This innovative material has quickly gained traction among leading e-commerce companies seeking to optimize their shipping operations.

Understanding Corrugated Plastic Technology

Material Composition and Structure

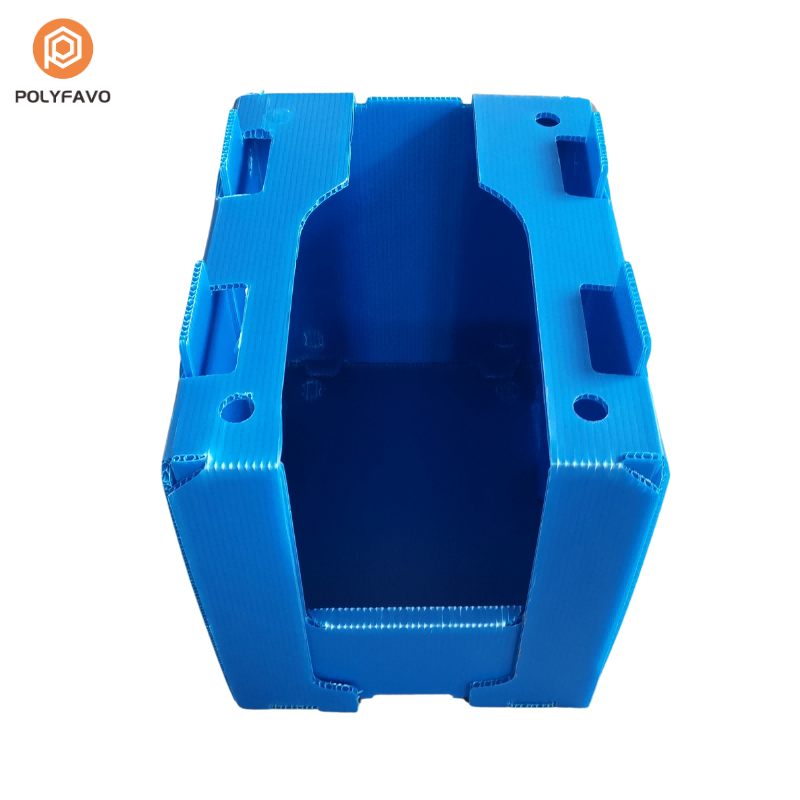

Corrugated plastic packaging consists of three layers: two flat outer sheets with a fluted middle layer. This unique construction creates air pockets that provide exceptional strength while maintaining minimal weight. The polymer-based material offers superior resistance to moisture, chemicals, and temperature variations compared to traditional corrugated cardboard.

The manufacturing process involves extruding polypropylene or polyethylene into specific patterns that maximize structural integrity. This results in a material that weighs significantly less than conventional packaging options while providing comparable or superior protection levels.

Advanced Design Features

Modern corrugated plastic packaging incorporates innovative design elements that enhance its functionality. The material can be engineered with varying flute sizes and configurations to meet specific shipping requirements. Manufacturers can adjust the thickness and density of the layers to create customized solutions for different product categories.

The versatility of corrugated plastic allows for the integration of special features such as anti-static properties, UV protection, and flame-retardant characteristics. These adaptable properties make it an ideal choice for e-commerce businesses shipping diverse product lines.

Weight Reduction Benefits

Quantifiable Cost Savings

The implementation of corrugated plastic packaging can lead to substantial reductions in shipping expenses. By decreasing package weight by up to 30% compared to traditional materials, businesses can significantly lower their transportation costs. This weight reduction directly impacts fuel consumption and enables more efficient use of cargo space.

Studies have shown that e-commerce companies switching to corrugated plastic packaging can achieve annual savings of up to 15% on their overall shipping expenses. These savings become particularly significant for businesses handling high shipping volumes or operating on international scales.

Environmental Impact

The lighter weight of corrugated plastic packaging contributes to reduced carbon emissions during transportation. Less fuel consumption means a smaller carbon footprint for each shipment. Additionally, the material's durability allows for multiple uses, further enhancing its environmental benefits.

Many corrugated plastic packaging solutions are now manufactured using recycled materials and can be fully recycled at the end of their lifecycle. This circular economy approach appeals to environmentally conscious consumers and helps businesses meet their sustainability goals.

Implementation Strategies

Integration with Existing Systems

Transitioning to corrugated plastic packaging requires careful planning and execution. Companies must evaluate their current packaging processes and identify areas where the new material can provide maximum benefit. This includes assessing handling equipment, storage requirements, and shipping partner capabilities.

Successful implementation often involves a phased approach, starting with specific product lines or shipping routes before expanding to broader operations. This method allows for proper testing and optimization of the new packaging solution while minimizing disruption to existing workflows.

Staff Training and Quality Control

Proper handling and packing techniques are essential for maximizing the benefits of corrugated plastic packaging. Staff training programs should focus on material properties, optimal packing methods, and quality control procedures. Regular monitoring and feedback systems help maintain consistent packaging standards across operations.

Quality control measures should include regular testing of package integrity, weight verification, and performance monitoring under various shipping conditions. This ensures that the weight reduction benefits are achieved without compromising product protection.

Future Developments

Technological Advancements

The corrugated plastic packaging industry continues to innovate, with new developments focusing on even lighter materials and enhanced performance characteristics. Research into advanced polymer blends and manufacturing techniques promises to further reduce weight while improving strength and durability.

Emerging technologies such as smart packaging integration and improved recycling methods are set to revolutionize how corrugated plastic packaging is used in e-commerce. These developments will provide additional value beyond simple weight reduction.

Market Trends and Adoption

Industry analysts predict accelerated adoption of corrugated plastic packaging across the e-commerce sector. Growing awareness of environmental issues and increasing pressure to reduce shipping costs are driving this trend. Companies that embrace this technology early are likely to gain competitive advantages in the marketplace.

The market for corrugated plastic packaging is expected to expand significantly in the coming years, with new applications and innovations continuing to emerge. This growth will likely lead to improved accessibility and cost-effectiveness for businesses of all sizes.

Frequently Asked Questions

What makes corrugated plastic packaging different from traditional materials?

Corrugated plastic packaging combines lightweight polymer materials with a unique three-layer structure featuring fluted middle sections. This design provides superior strength-to-weight ratio, moisture resistance, and reusability compared to traditional packaging materials.

How much weight reduction can businesses expect?

Typically, businesses can achieve weight reductions of 20-30% when switching to corrugated plastic packaging from traditional materials. The exact reduction depends on factors such as package size, design specifications, and product requirements.

Is corrugated plastic packaging environmentally sustainable?

Yes, corrugated plastic packaging offers several environmental benefits. It's recyclable, reusable, and its lightweight nature reduces transportation-related emissions. Many manufacturers now use recycled content in production, further improving its environmental profile.