Understanding the Financial Impact of Packaging Material Choices

The choice of packaging materials can significantly impact a company's bottom line, operational efficiency, and environmental footprint. As businesses seek more sustainable and cost-effective solutions, the shift from traditional cardboard to corrugated plastic has emerged as a strategic move that delivers substantial financial benefits. This comprehensive analysis explores how this switch can transform your packaging operations and generate long-term cost savings.

Material Durability and Reusability Benefits

Extended Lifecycle and Multiple Use Advantages

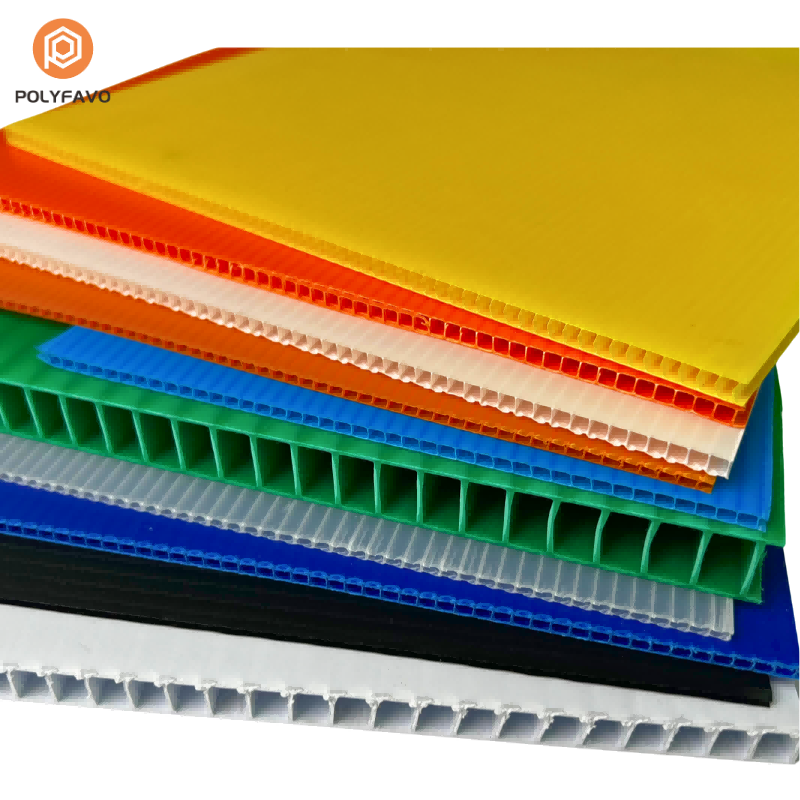

While cardboard boxes typically last for one to three uses before showing significant wear, corrugated plastic containers can withstand hundreds of cycles. This extended lifespan translates into remarkable cost savings, as businesses can avoid frequent replacement purchases. A single corrugated plastic container can effectively replace dozens of cardboard boxes over its lifetime, resulting in substantial procurement cost reduction.

The durability of corrugated plastic extends beyond just the number of uses. These containers maintain their structural integrity even when exposed to moisture, varying temperatures, and rough handling. This resilience ensures consistent performance throughout their lifecycle, eliminating the need for emergency replacements or double-boxing that often occurs with degraded cardboard.

Weather Resistance and Storage Cost Reduction

Unlike cardboard, corrugated plastic remains unaffected by rain, humidity, and temperature fluctuations. This weather resistance eliminates the need for climate-controlled storage facilities, potentially reducing warehouse overhead costs by 15-25%. Companies can safely store corrugated plastic containers outdoors or in basic sheltered areas without risking material degradation.

The moisture-resistant properties of corrugated plastic also prevent product damage during transport and storage, reducing insurance claims and replacement costs. This protection is particularly valuable for businesses operating in humid climates or handling temperature-sensitive goods.

Operational Efficiency and Labor Cost Savings

Streamlined Handling Processes

The consistent shape retention of corrugated plastic containers significantly improves handling efficiency. Workers can stack, store, and transport these containers more quickly and safely compared to cardboard boxes that may collapse or require careful handling. This improved handling can reduce labor costs by up to 30% in warehouse operations.

Additionally, corrugated plastic containers often feature standardized designs with integrated handling features, such as handholds or interlocking edges. These ergonomic elements reduce worker fatigue and the risk of workplace injuries, potentially lowering insurance premiums and workers' compensation claims.

Automated System Compatibility

Modern corrugated plastic containers are designed to work seamlessly with automated handling systems, conveyor belts, and robotic picking systems. This compatibility eliminates the need for manual interventions often required with damaged or warped cardboard boxes, leading to increased throughput and reduced labor requirements.

The dimensional stability of corrugated plastic also ensures consistent scanner readings and reliable automated sorting, reducing errors and associated costs in logistics operations.

Environmental Impact and Regulatory Compliance

Waste Reduction and Disposal Savings

The switch to corrugated plastic dramatically reduces waste management costs. While cardboard requires regular disposal or recycling, corrugated plastic's extended lifespan minimizes waste generation. Companies can see up to 90% reduction in packaging-related waste disposal costs after transitioning to corrugated plastic solutions.

Furthermore, when corrugated plastic containers eventually reach their end of life, they are fully recyclable and often have a higher recycling value than cardboard, potentially generating additional revenue streams through material recovery programs.

Regulatory Compliance and Carbon Footprint

As environmental regulations become stricter, using corrugated plastic can help businesses stay ahead of compliance requirements. Many regions now impose fees or taxes on single-use packaging materials, making reusable corrugated plastic an increasingly cost-effective choice. The reduced carbon footprint associated with reusable packaging can also help companies meet sustainability targets and avoid potential future carbon taxes.

Implementation and Return on Investment

Initial Investment Considerations

While corrugated plastic containers typically have a higher upfront cost compared to cardboard, the return on investment (ROI) is usually achieved within 6-12 months of implementation. This calculation factors in the eliminated need for constant cardboard replacement, reduced product damage, improved operational efficiency, and decreased waste management costs.

Companies can optimize their investment by starting with high-volume shipping routes or product lines where the benefits of durability and reusability will have the most immediate impact on cost reduction.

Long-term Financial Benefits

The long-term financial advantages of switching to corrugated plastic extend beyond direct material costs. Businesses often report improved customer satisfaction due to better product protection, leading to increased repeat business and reduced returns handling costs. The professional appearance and consistency of corrugated plastic containers can also enhance brand perception and market positioning.

Frequently Asked Questions

How long do corrugated plastic containers typically last?

Corrugated plastic containers can last for hundreds of use cycles when properly maintained, with many businesses reporting lifespans of 3-5 years under normal operating conditions. This durability far exceeds the 1-3 use limit of traditional cardboard boxes.

What industries benefit most from switching to corrugated plastic?

Industries with high-volume shipping needs, frequent product movement, or exposure to varying environmental conditions see the greatest benefits. This includes automotive parts suppliers, food and beverage distributors, retail supply chains, and manufacturing operations with closed-loop logistics systems.

Are there any hidden costs in transitioning to corrugated plastic?

The main considerations are initial investment costs and potential modifications to storage systems. However, these costs are typically offset by reduced operational expenses within the first year. Some businesses may need to adjust their reverse logistics processes to effectively manage container returns and tracking.