Modern warehouses face constant pressure to optimize storage space while maintaining efficiency and cost-effectiveness. The challenge of maximizing cubic storage capacity without compromising accessibility has led many logistics professionals to explore innovative packaging solutions. Among these solutions, the pallet sleeve box has emerged as a game-changing storage system that transforms how businesses approach warehouse organization and inventory management.

These versatile storage containers offer unprecedented flexibility in warehouse design and inventory control. By creating uniform, stackable units that maximize vertical space utilization, businesses can dramatically increase their storage density while reducing operational costs. The implementation of such systems requires careful planning and understanding of best practices to achieve optimal results.

Understanding Pallet Sleeve Box Technology

Core Design Principles

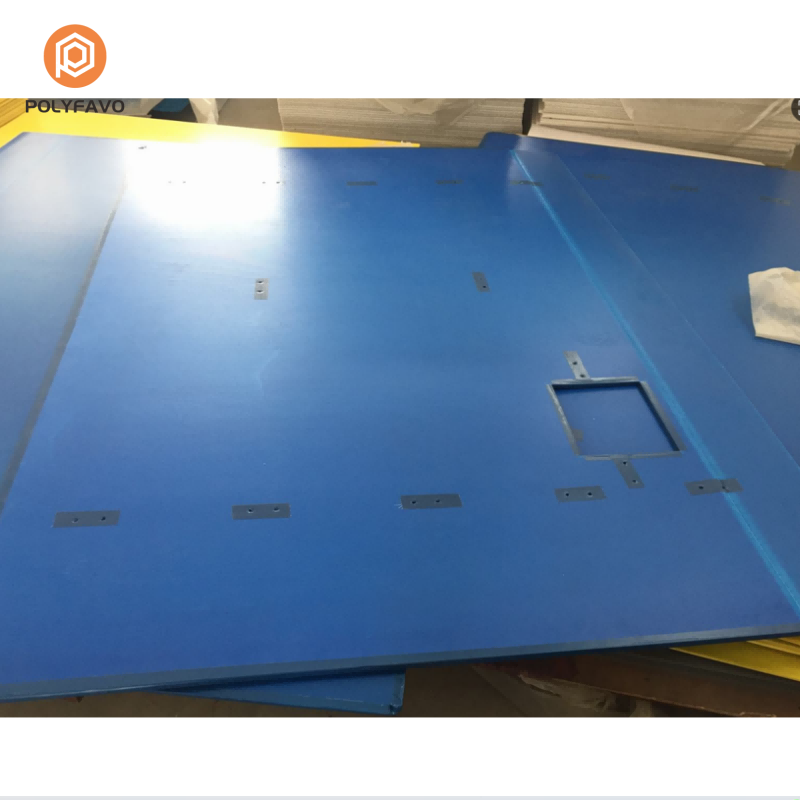

The fundamental concept behind pallet sleeve box systems revolves around modular design and space optimization. These containers feature collapsible walls that extend upward from a standard pallet base, creating a secure containment system for various products. The walls typically fold down when not in use, allowing for efficient return shipping and storage of empty containers.

The engineering behind these systems prioritizes structural integrity while maintaining lightweight characteristics. Advanced materials and reinforcement techniques ensure that multiple units can be safely stacked without compromising the contents below. This balance between strength and weight becomes crucial when calculating overall storage efficiency and handling costs.

Manufacturers have developed various configurations to accommodate different product types and warehouse requirements. Some systems feature removable walls for partial access, while others incorporate specialized corner reinforcements for heavy-duty applications. The selection of appropriate configurations directly impacts the success of space maximization efforts.

Material Composition and Durability

Modern pallet sleeve box systems utilize high-grade corrugated materials, plastic composites, or metal frameworks depending on application requirements. Corrugated versions offer excellent cost-effectiveness for single-use or limited-cycle applications, while plastic and metal alternatives provide superior durability for repeated use scenarios.

The choice of materials significantly influences both initial investment costs and long-term operational expenses. Businesses must evaluate their specific usage patterns, product characteristics, and handling environments to determine the most cost-effective material selection. Environmental factors such as humidity, temperature variations, and exposure to chemicals also play critical roles in material selection.

Quality control standards in manufacturing ensure consistent performance across different production batches. This consistency becomes essential when implementing large-scale storage systems where uniform dimensions and load-bearing capabilities are required throughout the warehouse operation.

Strategic Implementation for Maximum Efficiency

Warehouse Layout Optimization

Successful implementation begins with comprehensive analysis of existing warehouse layouts and identification of underutilized spaces. The modular nature of pallet sleeve box systems allows for creative solutions in areas previously considered unsuitable for traditional storage methods.

Vertical space utilization becomes a primary focus when integrating these systems. Standard ceiling heights in industrial facilities often provide opportunities for additional storage levels that remain accessible through proper planning and equipment selection. The key lies in balancing maximum height utilization with practical handling requirements.

Traffic flow patterns within the warehouse must be carefully considered to ensure that increased storage density does not impede operational efficiency. Strategic placement of pallet sleeve box systems can actually improve workflow by creating more defined storage zones and reducing travel distances for picking operations.

Integration with Existing Systems

Compatibility with current material handling equipment represents a crucial factor in successful implementation. Most pallet sleeve box systems are designed to work with standard forklifts, pallet jacks, and automated handling systems, but specific clearance requirements and weight distributions must be verified during planning phases.

Warehouse management system integration ensures that the benefits of increased storage capacity translate into improved inventory accuracy and operational control. Modern WMS platforms can accommodate the unique characteristics of sleeve box systems, providing enhanced visibility into storage utilization and product locations.

Staff training programs become essential components of successful implementation. Personnel must understand proper assembly, handling, and stacking procedures to maintain system integrity and safety standards. Comprehensive training reduces the risk of damage and ensures consistent performance across all shifts and operators.

Cost-Benefit Analysis and ROI Calculations

Initial Investment Considerations

The financial evaluation of pallet sleeve box systems extends beyond simple purchase prices to encompass total cost of ownership calculations. Initial investments include not only the containers themselves but also any required modifications to existing infrastructure, training programs, and system integration costs.

Comparison studies with alternative storage solutions reveal that sleeve box systems often provide superior return on investment through increased storage density and reduced facility requirements. The ability to store more products in existing space eliminates or delays the need for facility expansion, representing significant cost savings.

Financing options and lease arrangements provide flexibility for businesses seeking to implement these systems without major capital expenditures. Many suppliers offer comprehensive packages that include training, maintenance, and replacement components, simplifying budget planning and operational management.

Operational Savings and Efficiency Gains

Labor cost reductions emerge through improved organization and reduced handling requirements. The standardized dimensions of pallet sleeve box systems streamline picking operations and reduce the time required for inventory management tasks. These efficiency gains compound over time, providing substantial operational savings.

Transportation cost optimization occurs through better load utilization and reduced packaging requirements. The collapsible nature of empty containers allows for more efficient return shipping, while the protective characteristics may eliminate the need for additional packaging materials.

Insurance and risk management benefits arise from improved product protection and reduced damage rates. The enclosed nature of these systems provides better security for stored items while reducing exposure to environmental factors that could cause deterioration or contamination.

Industry Applications and Success Stories

Manufacturing and Production Environments

Manufacturing facilities have found particular success with pallet sleeve box systems in managing work-in-process inventory and finished goods storage. The ability to create temporary storage areas that can be easily reconfigured supports lean manufacturing principles and just-in-time production strategies.

Automotive industry applications demonstrate the versatility of these systems in handling diverse component types and sizes. From small fasteners to large sub-assemblies, the adaptable nature of sleeve box systems accommodates varying storage requirements while maintaining organized, accessible inventory.

Food and beverage operations benefit from the hygienic characteristics of properly designed sleeve box systems. The enclosed storage environment protects products from contamination while allowing for efficient cleaning and sanitization procedures between uses.

Distribution and Logistics Centers

Third-party logistics providers have embraced these systems for their ability to accommodate multiple client requirements within shared facilities. The modular nature allows for dedicated storage areas that can be easily modified as client needs change, providing operational flexibility without permanent infrastructure modifications.

E-commerce fulfillment centers utilize pallet sleeve box systems to manage seasonal inventory fluctuations and promotional stock. The quick setup and breakdown capabilities support rapid response to changing demand patterns while maintaining organized storage environments.

Cross-docking operations benefit from the temporary containment capabilities of these systems. Products can be efficiently sorted and staged for outbound shipments without requiring permanent storage infrastructure, improving throughput and reducing handling costs.

Maintenance and Long-Term Performance

Preventive Care Strategies

Regular inspection protocols ensure continued performance and safety of pallet sleeve box systems throughout their operational life. Visual checks for damage, wear patterns, and structural integrity should be incorporated into routine warehouse maintenance schedules to identify potential issues before they impact operations.

Proper handling procedures minimize stress on connection points and folding mechanisms, extending system lifespan and reducing replacement costs. Training programs should emphasize correct assembly and disassembly techniques to prevent damage during routine operations.

Environmental monitoring becomes important in facilities where temperature, humidity, or chemical exposure could affect system materials. Appropriate storage conditions for unused containers and regular cleaning protocols maintain system reliability and appearance.

Performance Monitoring and Optimization

Key performance indicators for pallet sleeve box systems include utilization rates, damage frequencies, and operational efficiency metrics. Regular monitoring of these indicators provides insights into system performance and opportunities for improvement.

Continuous improvement initiatives should focus on identifying bottlenecks or inefficiencies in current implementations. Feedback from warehouse personnel often reveals practical modifications that can enhance system performance and user satisfaction.

Technology integration opportunities continue to evolve, with sensor-equipped systems and IoT connectivity providing enhanced monitoring and control capabilities. These advanced features can provide real-time insights into storage utilization and system performance.

FAQ

What weight capacity can pallet sleeve box systems safely handle?

Weight capacity varies significantly based on materials, design specifications, and stacking configurations. Most standard corrugated systems support 1,000-2,000 pounds per unit, while heavy-duty plastic or metal versions can handle 3,000-5,000 pounds or more. Always consult manufacturer specifications and conduct load testing for your specific applications to ensure safe operation.

How do pallet sleeve box systems compare to traditional racking in terms of storage density?

Pallet sleeve box systems typically achieve 15-30% better storage density than traditional selective racking due to eliminated aisle requirements between rows and optimized vertical space utilization. The exact improvement depends on facility layout, product characteristics, and stacking heights achieved. Dense storage configurations can approach warehouse cube utilization rates of 80-85% compared to 60-70% for conventional systems.

Can these systems be customized for specific product requirements?

Yes, most manufacturers offer extensive customization options including custom dimensions, specialized corner reinforcements, access panels, ventilation features, and material selections. Custom printing and labeling options support branding and identification requirements. Lead times for custom configurations typically range from 2-6 weeks depending on complexity and quantity requirements.

What maintenance is required to keep pallet sleeve box systems functioning properly?

Maintenance requirements are generally minimal, consisting primarily of visual inspections for damage, proper storage of unused units, and adherence to weight and stacking limits. Corrugated systems may require replacement after 10-20 cycles depending on handling conditions, while plastic and metal systems can last hundreds of cycles with proper care. Regular cleaning and protection from environmental extremes extend system lifespan significantly.

Table of Contents

- Understanding Pallet Sleeve Box Technology

- Strategic Implementation for Maximum Efficiency

- Cost-Benefit Analysis and ROI Calculations

- Industry Applications and Success Stories

- Maintenance and Long-Term Performance

-

FAQ

- What weight capacity can pallet sleeve box systems safely handle?

- How do pallet sleeve box systems compare to traditional racking in terms of storage density?

- Can these systems be customized for specific product requirements?

- What maintenance is required to keep pallet sleeve box systems functioning properly?