Foldable Pallet Sleeve Pack

Reusable bulk containers, especially the corrugated plastic sleeve pack (also called the “sleeve box” or “pallet pack”), are growing in popularity. Originating in Europe as an alternative to the Gaylord box, this innovative packaging option is now making headway in North America. As more people become aware of its many advantages over traditional packaging, it is rapidly being adopted. Sleeve packs offer flexibility and cost - effectiveness. What's more, they are an eco - friendly alternative to single - use packaging, making them an attractive solution for a wide range of applications.

- Overview

- Recommended Products

Core Components:

● Pallet Base:

Typically made from durable materials like HDPE or polypropylene.

Provides a stable foundation for the goods.

Designed with forklift entry points for easy handling.

Can be solid or have a grid structure for added strength.

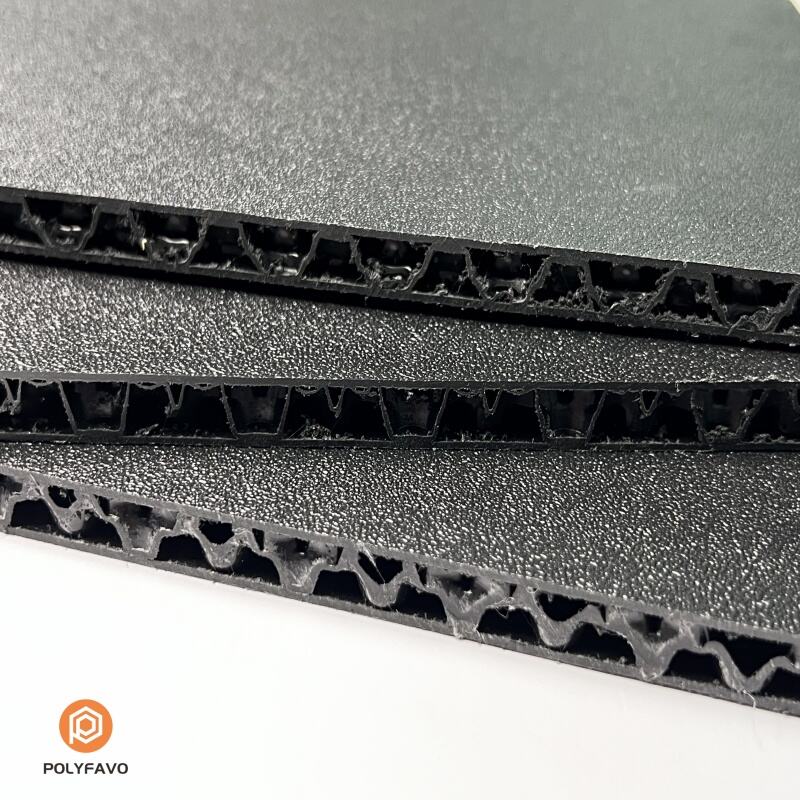

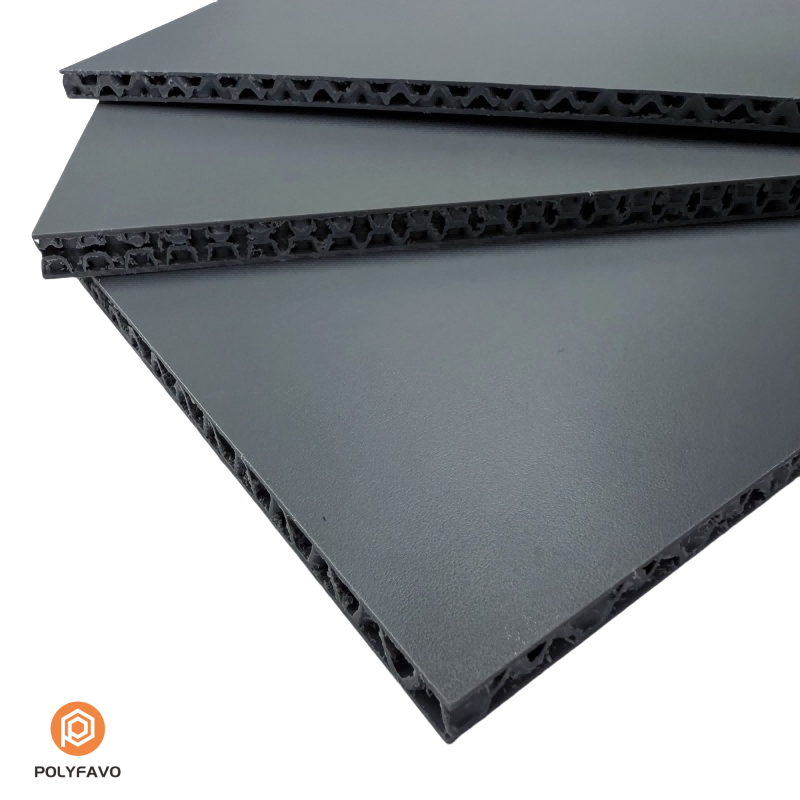

● Foldable Sleeve:

The main body of the container, forming the vertical walls.

Constructed from materials like polypropylene, often in a honeycomb or corrugated structure for strength.

Designed to fold down when empty, significantly reducing storage space.

Folding mechanisms vary, including "Z-fold" or "M-fold" patterns, optimized for different dimensions and space efficiency.

Provides protection against dust, moisture, and physical damage.

● Top Lid (Optional, but common):

Made from materials similar to the pallet base or sleeve.

Provides a secure and protective cover for the goods.

Often designed to interlock with the sleeve and pallet base for stability.

Allows for stacking of multiple packs, maximizing storage space.

Key Features and Benefits:

● Collapsibility:

Reduces return shipping costs and storage space when empty.

Increases efficiency in logistics and warehousing.

● Reusability:

An environmentally friendly alternative to single-use packaging.

Reduces waste and packaging costs.

● Durability:

Withstands heavy loads and repeated use in industrial environments.

Protects goods from damage during transport and storage.

● Customization:

Sizes, materials, and features can be tailored to specific needs.

Options for access doors, custom printing, and specialized designs.

● Protection:

Provides a robust barrier against dust, moisture, and physical impacts.

● Efficiency:

Streamlines material handling and storage operations.

Applications:

● Automotive Industry: Transporting parts and components.

● Manufacturing and Distribution: Moving bulk goods efficiently.

● Food and Beverage Industry: Storing and transporting products.

● Pharmaceutical Industry: Protecting sensitive goods.

● Logistics and Warehousing: Optimizing storage and transport.

● In essence, a foldable pallet sleeve pack is a versatile and efficient packaging solution that offers a combination of durability, reusability, and space-saving features.

Product parameter list

Product Name |

M Fold Pallet Sleeve |

Brand |

POLYFAVO |

Style |

Foldable Sleeve Pack |

Size |

1200mm x 1000mm |

Height |

860/1000/1640mm/ custom size |

Weight |

27.5kg |

Sleeve Pack Thickness |

8-12mm |

Litres |

860 |

Recycled Plastic |

No |

Volume (L) |

885L |

Material |

100% Recycled HDPE Base (Lid and Pallet) , and 100% virgin PP sleeve - Overall 67% recycled |

|

Can be printed with your branding

|

Yes |

Type |

Solid |

Printing |

On demand |

|

External Length (mm)

|

Lid/Pallet: 700-1470mm Sleeve pack: 600-1430mm |

External Width (mm) |

Lid/Pallet 400-1150mm Sleeve pack: 360-1110mm |

Exernal height |

500-1200mm |

|

Folded Height (mm)

|

229mm |

|

Trailer/Truck Quantity

|

52 Full / 286 Folded |

|

Max Load per Box

|

500kg (Stacked 2:1) |

|

Pallet Stack Quantity

|

11 |

Pallet type |

9 feet, closed pallet deck |

|

Static (kg)

|

1000kg |

|

Dynamic (kg)

|

500kg |

Max load per box (kg) |

500kg |

Max stack load (kg) |

1000kg |

Optional features |

Pallet/Sleeve locks (Pallet interlocks with lid to keep stacked containers stable.) Sliding tabs snap into place securing sleeve, pallet and lid. Handles |

|

Foldable

|

Yes |

|

Rackable

|

No |

Base Configuration |

On nine feet |

Stocked color |

Grey, Black |

Available in other colors |

No |

Stacking layer |

1+2 |

Lid |

Included |

Features |

● Thermoformed plastic 4-way entry pallet and lid. ● ①Closed base and slides with drop door and lid②Two handles ● The groove design of the lids ensures stable stacking and is not easy to fall off. ● Up to 80% less volume on the return cycle ● More than 70% lighter than traditional pallet cages ● 100% recyclable ● Stackable ● Environmentally friendly ● Nestable ● Foldable, high folding ratio ● 100% recyclable ● Does not absorb liquids and easy to clean ● Long life span: 3+ years ● Full water and dust protection ● Resistant to most oils and acids ● Suitable for intelligent logistics turnover ● Efficient! Pack, stack, ship, fold, return - repeat! ● Thermal insulation ● No deformation ● Non-toxic ● Odorless ● High toughness ● Moisture resistant ● Bend resistant ● Flame retardant ● UV radiation resistant ● Dirt resistant ● Corrosion resistant ● High impact resistant ● Chemical resistant ● Weather resistant ● Stand wear and tear ● Anti-aging ● Rot resistant ● Pest resistant ● Fungus resistant ● Break resistant ● Easily cleaned ● Easy to handle |

Accessories |

1 HDPE lid(Closed base and slides with drop door and lid) 1 PP sleeve 1 HDPE pallet 2 Belt handles 4 Belt locks 1 Label holder 2 Velcros 1 Loading door |

Application |

logistics, packaging, storage, turn over of auto parts, electronics, batteries, machine parts, and medical supplies |

Packaging |

Fold and Wrap |

Place of Origin |

China |

FOB port |

Qingdao |

OTHER PALLET & LID SIZE

Blow Molding Type

Model |

Pallet Outer Diameter |

Pallet Inner Diameter |

Pallet Weight |

Lid Weight |

STACKING LAYER |

LOADING WEIGHT |

BM8060 |

800*600 |

740*540 |

7kg |

5kg |

1+2 |

300KGS |

BM1110 |

1100*1000 |

1050*950 |

10kg |

7.5kg |

1+2 |

300KGS |

BM1111 |

1100*1100 |

1055*1055 |

10kg |

8kg |

1+2 |

300KGS |

BM1198 |

1150*985 |

1100*935 |

10kg |

9kg |

1+2 |

300KGS |

BM1515 |

1150*1150 |

1105*1105 |

10.5kg |

8.5kg |

1+2 |

300KGS |

BM1280 |

1200*800 |

1140*740 |

10kg |

9kg |

1+2 |

300KGS |

BM1210 |

1200*1000 |

1140*940 |

11kg |

10kg |

1+2 |

300KGS |

BM1211 |

1220*1150 |

1170*1105 |

11kg |

9kg |

1+2 |

300KGS |

BM1210-3 |

1230*1030 |

1170*970 |

11.5kg |

8.5kg |

1+2 |

300KGS |

BM1311 |

1350*1140 |

1290*1080 |

14kg |

12kg |

1+2 |

300KGS |

BM1411 |

1470*1140 |

1410*1080 |

15kg |

13kg |

1+2 |

300KGS |

BM1611 |

1600*1140 |

1540*1085 |

20kg |

13kg |

1+2 |

300KGS |

BM1811 |

1840×1130 |

1540*1080 |

23kg |

12kg |

1+2 |

300KGS |

BM2011 |

2070*1150 |

2035*1115 |

30kg |

16kg |

1+2 |

300KGS |

Injection Type

Model |

Pallet Outer Size |

Pallet Inner Size |

FOLDING HEIGHT |

LOADING WEIGHT |

STACKING LAYERS |

REMARK |

ZS1210 |

1200*1000 |

1130*930 |

240 |

500 |

5 |

9 FEET/3 RUNNERS |

ZS1280 |

1200*800 |

1130*730 |

240 |

500 |

5 |

9 FEET/3 RUNNERS |

ZS1198 |

1140*980 |

1070*910 |

240 |

500 |

5 |

9 FEET/3 RUNNERS |

ZS1111 |

1140*1140 |

1070*1070 |

240 |

500 |

5 |

9 FEET/3 RUNNERS |

1.Lashing Belts and handle belts can be added | ||||||

2. 9 feets/3 runners are for options. | ||||||

3. Steel Tube can be added in pallet and lid for higher loading weight. | ||||||