When selecting the ideal plastic sheeting material for your industrial or commercial applications, the choice between coroplast sheets and PP honeycomb board can significantly impact your project's success. Both materials offer unique advantages in packaging, signage, construction, and manufacturing applications. Understanding the fundamental differences between these twin-wall plastic solutions will help you make an informed decision that aligns with your specific requirements and budget constraints.

The decision between these two polypropylene-based materials involves careful consideration of factors including structural strength, chemical resistance, thermal properties, and cost-effectiveness. Each material has carved out distinct market segments based on their performance characteristics and manufacturing processes. This comprehensive analysis will examine the key differences between coroplast sheets and PP honeycomb board to guide your material selection process.

Understanding Coroplast Sheet Construction and Properties

Manufacturing Process and Material Composition

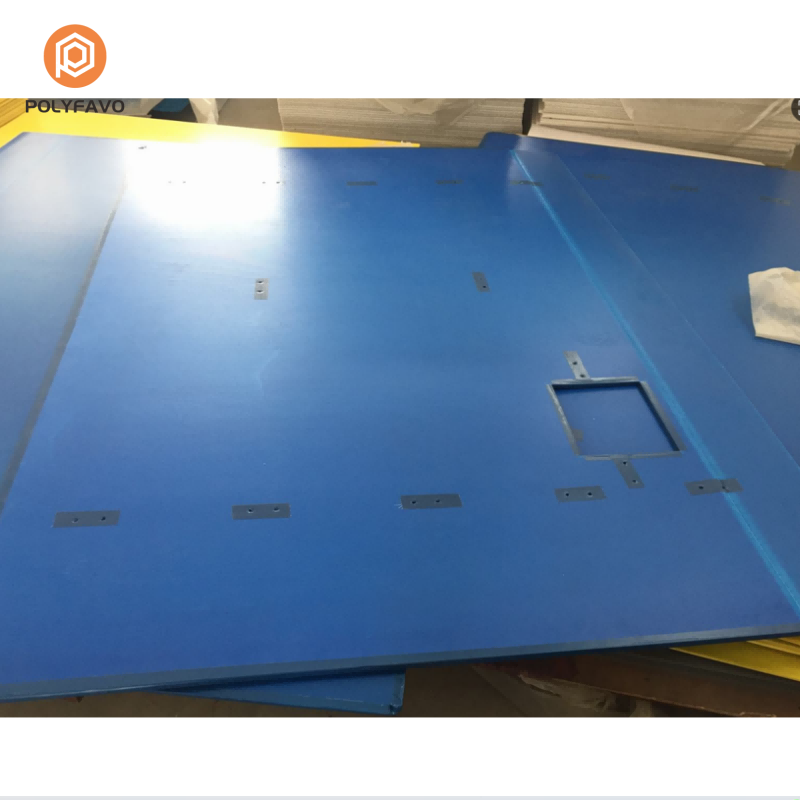

Coroplast sheets are manufactured through an extrusion process that creates a twin-wall fluted structure from polypropylene resin. The manufacturing process involves melting polypropylene pellets and forcing the molten material through specially designed dies that form parallel channels or flutes between two solid sheets. This creates a lightweight yet structurally sound panel with excellent strength-to-weight ratios.

The fluted design provides inherent structural integrity while maintaining material efficiency. The walls of the corrugated plastic sheet are typically between 2mm to 10mm thick, with the flute direction determining the material's bending characteristics. The continuous extrusion process ensures consistent wall thickness and flute spacing throughout the sheet, resulting in predictable performance characteristics across different applications.

Physical and Chemical Properties

Coroplast sheets exhibit excellent chemical resistance to most acids, bases, and organic solvents, making them suitable for harsh industrial environments. The material maintains its structural integrity across a wide temperature range, typically from -40°F to 180°F, without significant dimensional changes or brittleness. The non-absorptive surface resists moisture, oils, and many chemicals that would degrade other materials.

The twin-wall construction provides superior impact resistance compared to solid sheets of similar weight. The air chambers within the fluted structure act as shock absorbers, distributing impact forces across the panel surface. This characteristic makes corrugated plastic sheet particularly valuable in protective packaging and temporary construction applications where durability is essential.

PP Honeycomb Board Architecture and Characteristics

Honeycomb Structure Design

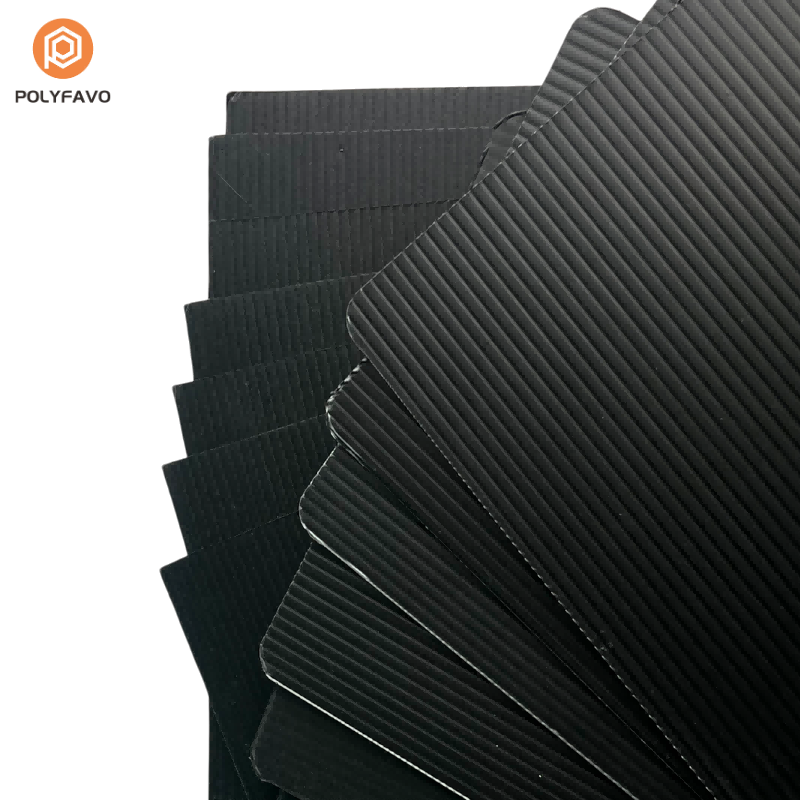

PP honeycomb board features a hexagonal cell structure sandwiched between two solid polypropylene face sheets. This honeycomb architecture maximizes structural strength while minimizing material usage, creating an exceptionally rigid panel with outstanding compression and bending strength. The hexagonal cells distribute loads efficiently across the panel surface, providing superior performance in structural applications.

The manufacturing process involves thermoforming or adhesively bonding the honeycomb core to the face sheets, creating a composite structure with enhanced mechanical properties. The cell size and wall thickness can be varied to optimize the material for specific applications, allowing manufacturers to fine-tune the balance between weight, strength, and cost.

Performance Advantages and Applications

The honeycomb structure provides exceptional flatness and dimensional stability, making PP honeycomb board ideal for applications requiring precise tolerances and minimal deflection. The material exhibits superior compression strength compared to corrugated plastic sheets, making it suitable for load-bearing applications and structural components. The closed-cell design also provides excellent insulation properties and moisture resistance.

PP honeycomb board maintains its structural integrity under sustained loads and resists creep deformation better than fluted materials. This characteristic makes it particularly valuable in furniture manufacturing, automotive components, and architectural applications where long-term dimensional stability is critical. The smooth face sheets also provide excellent printability for signage and display applications.

Comparative Analysis of Strength and Durability

Structural Performance Differences

When comparing structural performance, PP honeycomb board generally provides superior compression strength and rigidity due to its hexagonal cell architecture. The honeycomb structure distributes loads more effectively than the parallel flutes in corrugated plastic sheets, resulting in higher load-bearing capacity per unit weight. This makes honeycomb board the preferred choice for applications requiring maximum structural performance.

However, corrugated plastic sheets offer advantages in impact resistance and flexibility. The fluted structure allows for controlled bending and flexing without catastrophic failure, making it ideal for applications involving dynamic loading or thermal expansion. The material's ability to absorb energy through elastic deformation makes it excellent for protective packaging and temporary structures that must withstand handling stresses.

Longevity and Environmental Resistance

Both materials exhibit excellent resistance to environmental factors including UV radiation, moisture, and temperature fluctuations when properly formulated with appropriate additives. Corrugated plastic sheets typically show better performance in applications involving repeated flexing or vibration due to their inherent flexibility. The open flute design also allows for drainage and ventilation in outdoor applications.

PP honeycomb board's closed-cell structure provides superior protection against moisture infiltration and chemical permeation, making it ideal for applications requiring long-term exposure to harsh environments. The solid face sheets also resist surface wear and maintain appearance longer than the exposed flute edges of corrugated materials in high-traffic applications.

Cost Analysis and Economic Considerations

Manufacturing and Material Costs

Corrugated plastic sheets generally offer lower initial material costs due to their simpler manufacturing process and more efficient material utilization. The extrusion process requires less complex tooling and can produce continuous lengths with minimal waste. This cost advantage makes corrugated plastic sheets attractive for large-volume applications where initial cost is the primary consideration.

PP honeycomb board typically commands higher prices due to its more complex manufacturing process and the additional processing steps required to bond the core to the face sheets. However, the superior strength-to-weight ratio can result in lower total costs when material thickness and structural requirements are considered. The enhanced performance characteristics may justify the higher initial investment in demanding applications.

Total Cost of Ownership

When evaluating total cost of ownership, factors beyond initial material cost must be considered including installation complexity, maintenance requirements, and service life. PP honeycomb board's superior dimensional stability and resistance to creep may result in lower maintenance costs and longer replacement intervals in structural applications. The material's resistance to surface wear also maintains appearance and functionality longer in high-use environments.

Corrugated plastic sheets offer advantages in applications requiring frequent replacement or modification due to their lower cost and easier fabrication. The material's recyclability and compatibility with standard thermoplastic processing equipment also contribute to lower end-of-life disposal costs. These factors make corrugated plastic sheets more economical for temporary or frequently changed applications.

Application-Specific Selection Criteria

Packaging and Protection Applications

For packaging applications, corrugated plastic sheets excel due to their impact resistance, lightweight construction, and ability to absorb shock through elastic deformation. The material's flexibility allows it to conform to irregular shapes while maintaining protective properties. The open flute structure also provides cushioning through air compression, making it ideal for shipping containers and protective packaging systems.

PP honeycomb board is preferred for applications requiring rigid protection and precise dimensional control. The material's flat surfaces and superior compression resistance make it excellent for pallets, dividers, and structural packaging components. The closed-cell structure also provides better protection against moisture and contamination in sensitive product packaging applications.

Signage and Display Applications

Both materials serve effectively in signage applications, but with different advantages. Corrugated plastic sheets offer cost-effective solutions for temporary signage and outdoor applications where weather resistance and easy installation are priorities. The material's ability to flex without breaking makes it suitable for curved installations and applications subject to wind loading.

PP honeycomb board provides superior flatness and dimensional stability for high-quality permanent signage and display applications. The smooth face sheets accept graphics and vinyl applications better, while the rigid structure prevents warping and maintains professional appearance over extended periods. The material's superior surface finish also provides better print quality for direct printing applications.

Processing and Fabrication Considerations

Cutting and Machining Properties

Corrugated plastic sheets can be easily cut with standard tools including utility knives, saws, and laser cutting systems. The fluted structure allows for scoring and folding operations, enabling the creation of boxes and three-dimensional structures without additional fasteners. However, the hollow flutes can present challenges in certain machining operations that require solid material engagement.

PP honeycomb board requires more sophisticated cutting techniques due to its composite structure, but provides better edge quality and dimensional accuracy. The solid face sheets support conventional machining operations including routing, drilling, and milling. The material's dimensional stability during processing makes it suitable for precision fabrication operations requiring tight tolerances.

Joining and Assembly Methods

Assembly methods for corrugated plastic sheets include mechanical fastening, welding, and adhesive bonding. The fluted structure provides channels for running wires or supports, making it useful in electrical and structural applications. However, the hollow flutes can complicate certain joining methods that require solid material thickness for proper engagement.

PP honeycomb board's solid face sheets provide excellent surfaces for adhesive bonding and mechanical fastening. The material's dimensional stability ensures consistent joint quality and long-term reliability. The composite structure also allows for specialized joining techniques including insert bonding and edge sealing to create hermetic assemblies for demanding applications.

FAQ

What is the main structural difference between coroplast sheets and PP honeycomb board

The primary structural difference lies in their core architecture. Corrugated plastic sheets feature parallel flutes or channels running in one direction between two solid walls, while PP honeycomb board uses a hexagonal honeycomb core sandwiched between two solid face sheets. This difference significantly impacts their strength characteristics, with honeycomb providing superior compression strength and corrugated offering better impact resistance and flexibility.

Which material offers better value for temporary outdoor applications

Corrugated plastic sheets typically provide better value for temporary outdoor applications due to their lower cost, excellent weather resistance, and ability to withstand wind loading through flexible deformation. The material's impact resistance and ease of installation make it ideal for temporary signage, construction barriers, and protective covers where cost-effectiveness is prioritized over maximum structural performance.

How do the thermal properties of these materials compare

Both materials offer similar thermal resistance ranges, typically performing well between -40°F to 180°F. However, PP honeycomb board's closed-cell structure provides better insulation properties due to trapped air in the hexagonal cells, while corrugated plastic sheets allow air circulation through the flutes, which can be advantageous in ventilation applications but reduces insulation effectiveness.

Which material is more suitable for food contact applications

PP honeycomb board is generally preferred for direct food contact applications due to its closed-cell structure that prevents contamination infiltration and its smooth, easy-to-clean face sheets. While both materials can be formulated to meet food safety requirements, the honeycomb structure's resistance to moisture and bacterial penetration makes it more suitable for food processing and packaging applications requiring stringent hygiene standards.