When it comes to choosing the right material for professional signage, businesses face numerous options that vary significantly in cost, durability, and visual appeal. Among the most versatile and cost-effective solutions available today, coroplast sheets have emerged as the go-to choice for countless applications ranging from yard signs to indoor displays. These lightweight yet sturdy plastic sheets offer an exceptional combination of weather resistance, print quality, and affordability that makes them ideal for both temporary and semi-permanent signage needs.

Understanding the Unique Properties of Corrugated Plastic

Material Composition and Structure

Corrugated plastic, commonly known by the brand name Coroplast, consists of twin-wall polypropylene sheets with a fluted core structure. This unique design creates air pockets between two flat surfaces, resulting in excellent strength-to-weight ratios that surpass many traditional signage materials. The hollow core construction provides insulation properties while maintaining structural integrity under various environmental conditions.

The manufacturing process involves extruding polypropylene resin through specialized dies that create the characteristic corrugated pattern. This process ensures consistent wall thickness and uniform fluting throughout each sheet, contributing to the material's reliability and predictable performance across different applications. The resulting product exhibits exceptional dimensional stability and resistance to warping or bending under normal use conditions.

Thickness Variations and Applications

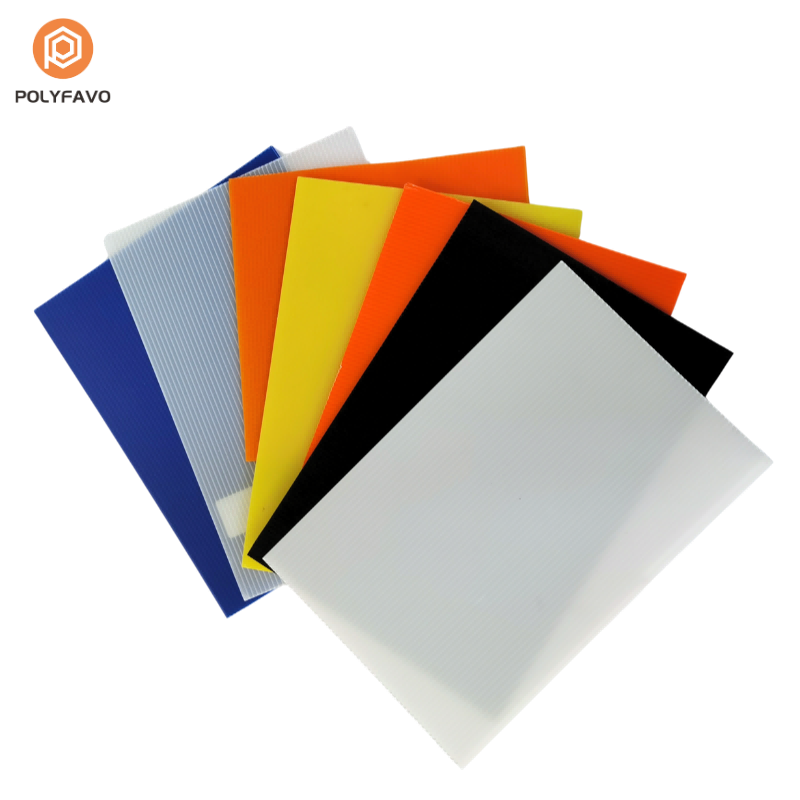

Standard coroplast sheets are available in multiple thickness options, typically ranging from 3mm to 10mm, with 4mm and 6mm being the most popular choices for signage applications. Thinner sheets work well for short-term indoor displays and lightweight outdoor signs, while thicker options provide enhanced durability for long-term outdoor installations and high-traffic areas.

The choice of thickness directly impacts the sign's wind resistance, structural stability, and overall lifespan. Professional sign makers often recommend 4mm thickness for standard yard signs and real estate applications, while 6mm or thicker sheets are preferred for larger format signs, construction site displays, and applications requiring extended outdoor exposure.

Weather Resistance and Durability Advantages

UV Stability and Color Retention

One of the most significant advantages of using coroplast sheets for signage lies in their exceptional UV resistance. The polypropylene material naturally resists ultraviolet radiation, preventing the degradation and brittleness that commonly affects other plastic materials when exposed to direct sunlight. This UV stability ensures that signs maintain their structural integrity and appearance even after months of outdoor exposure.

Modern manufacturing processes often incorporate UV stabilizers and additives that further enhance the material's resistance to sun damage. These improvements result in superior color retention for printed graphics and extended service life for the substrate itself. Field testing has demonstrated that properly manufactured corrugated plastic signs can maintain acceptable appearance standards for 12-18 months in outdoor environments.

Moisture and Chemical Resistance

The closed-cell structure of coroplast sheets provides excellent moisture resistance, preventing water absorption that could lead to warping, delamination, or dimensional changes. This characteristic makes the material particularly suitable for humid environments, coastal applications, and installations where occasional moisture exposure is expected.

Additionally, polypropylene exhibits strong resistance to most common chemicals, including cleaning solutions, automotive fluids, and industrial solvents. This chemical resistance ensures that signs remain intact and legible even in challenging industrial environments or areas with potential chemical exposure. The material's non-porous surface also facilitates easy cleaning and maintenance throughout the sign's service life.

Cost-Effectiveness and Economic Benefits

Material and Production Costs

The economic advantages of coroplast sheets extend beyond their initial purchase price to encompass the entire signage production process. The lightweight nature of corrugated plastic reduces shipping costs and handling expenses, while the material's ease of fabrication minimizes labor requirements during manufacturing and installation.

Compared to traditional materials like aluminum, wood, or foam board, corrugated plastic offers significant cost savings without compromising performance for most signage applications. The material's consistent quality and predictable properties also reduce waste and rework during production, contributing to overall cost efficiency for sign manufacturers and end users alike.

Long-Term Value Proposition

When evaluating signage materials, the total cost of ownership includes not only initial material costs but also installation, maintenance, and replacement expenses over time. Corrugated plastic excels in this comprehensive analysis due to its durability, low maintenance requirements, and recyclable properties that support sustainable business practices.

The material's resistance to vandalism and accidental damage further enhances its value proposition. Unlike rigid materials that crack or shatter upon impact, corrugated plastic typically rebounds from minor impacts without permanent damage. This resilience reduces replacement costs and extends the effective lifespan of signage investments.

Printing and Graphics Application Excellence

Surface Preparation and Ink Adhesion

The smooth, uniform surface of coroplast sheets provides an excellent foundation for various printing methods, including digital printing, screen printing, and vinyl application. The material's consistent surface energy and chemical composition ensure reliable ink adhesion and vibrant color reproduction across the entire sheet surface.

Surface treatments and corona discharge processes further enhance the material's printability by increasing surface energy and improving ink wetting characteristics. These treatments create microscopic surface modifications that promote stronger chemical bonds between inks and the substrate, resulting in improved durability and scratch resistance for printed graphics.

Color Vibrancy and Detail Resolution

Modern digital printing technologies work exceptionally well with corrugated plastic substrates, producing sharp text, fine details, and vibrant colors that rival more expensive signage materials. The material's white surface provides excellent contrast for dark colors while maintaining color accuracy for lighter tones and complex graphics.

The ability to achieve high-resolution printing on coroplast sheets makes them suitable for applications requiring detailed graphics, small text, or photographic reproductions. This versatility expands the material's applicability beyond simple text-based signs to include complex marketing displays, architectural graphics, and artistic installations.

Installation and Fabrication Simplicity

Cutting and Shaping Options

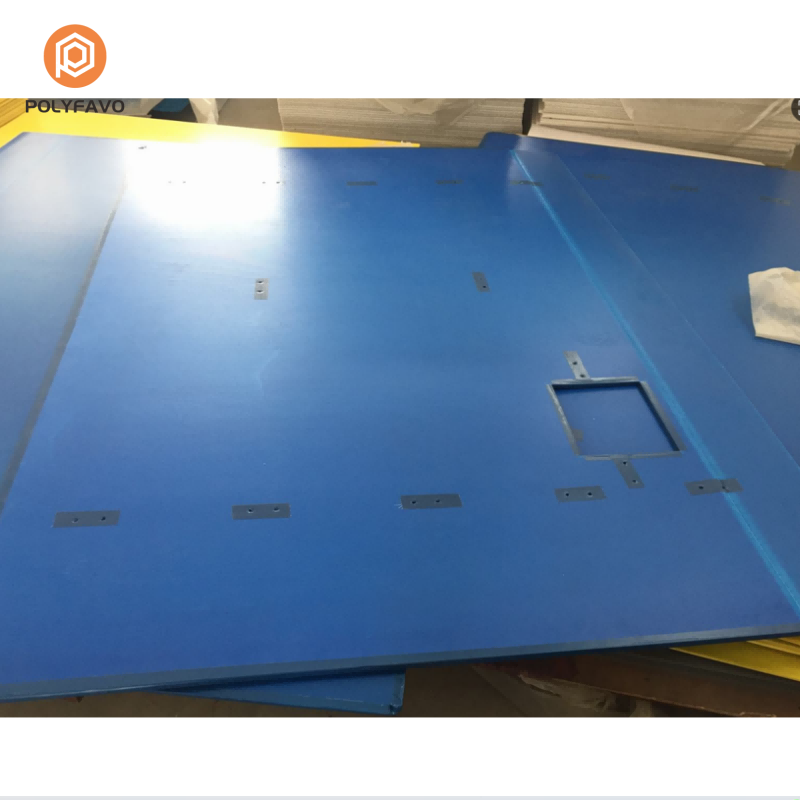

The ease of fabrication represents another compelling advantage of corrugated plastic for signage applications. Standard woodworking tools, utility knives, and specialized plastic cutting equipment can all be used to cut and shape coroplast sheets with minimal effort and excellent results. This accessibility allows both professional sign shops and DIY users to work with the material effectively.

The material's directional strength characteristics, determined by the flute orientation, can be leveraged during design and fabrication to optimize performance for specific applications. Cuts parallel to the flutes provide clean edges and maintain structural integrity, while perpendicular cuts may require additional finishing techniques to achieve professional appearances.

Mounting and Hardware Compatibility

Corrugated plastic accepts a wide variety of mounting hardware and installation methods, from simple stake mounting for yard signs to sophisticated frame systems for large-format displays. The material's consistent thickness and predictable hole-drilling characteristics simplify the installation process and ensure reliable mechanical connections.

Specialized hardware designed specifically for corrugated plastic, including snap-in grommets, push-through stakes, and clip systems, further streamline installation procedures while providing professional-quality results. These purpose-built solutions take advantage of the material's unique properties to create secure, weather-resistant installations with minimal tools and expertise required.

Environmental Impact and Sustainability

Recyclability and End-of-Life Considerations

Polypropylene, the base material for coroplast sheets, carries the recycling code #5 and can be processed through established plastic recycling streams in many regions. This recyclability supports sustainable business practices and helps organizations meet environmental responsibility goals while managing signage lifecycle costs.

The clean separation of inks and graphics from the substrate during recycling processes enables efficient material recovery and reduces waste streams. Many sign manufacturers have established take-back programs for used corrugated plastic signs, facilitating proper recycling and demonstrating environmental stewardship to their customers.

Carbon Footprint and Manufacturing Efficiency

The lightweight nature of corrugated plastic contributes to reduced carbon footprints throughout the signage supply chain. Lower shipping weights translate to decreased fuel consumption during transportation, while the material's durability reduces the frequency of replacement cycles and associated environmental impacts.

Manufacturing efficiency improvements in polypropylene production have consistently reduced energy consumption and emissions per unit of material produced. These ongoing improvements, combined with increased recycled content in new sheet production, continue to enhance the environmental profile of corrugated plastic signage solutions.

FAQ

How long do corrugated plastic signs typically last outdoors

Quality corrugated plastic signs can maintain acceptable appearance and functionality for 12-18 months in typical outdoor conditions, with some applications lasting up to 24 months depending on climate, UV exposure, and maintenance practices. The material's UV stabilizers and weather-resistant properties ensure gradual degradation rather than sudden failure, allowing for planned replacement schedules.

Can coroplast sheets be painted or decorated with markers

Yes, coroplast sheets accept various decoration methods including acrylic paints, permanent markers, and vinyl lettering. Surface preparation with light sanding or chemical etching may improve adhesion for some coating systems. However, digital printing or screen printing typically provides the most durable and professional-quality graphics for commercial signage applications.

What thickness of corrugated plastic works best for yard signs

For standard residential yard signs measuring 18x24 inches or smaller, 4mm thickness provides an optimal balance of cost, durability, and wind resistance. Larger signs or those requiring extended outdoor exposure benefit from 6mm thickness, while 3mm material works well for short-term indoor applications or protected outdoor locations.

Are there size limitations for corrugated plastic sheets

Standard sheet sizes range from 24x36 inches up to 48x96 inches, with custom sizes available from many manufacturers. Larger sheets may require special handling and shipping arrangements, but the material's lightweight properties make oversized applications more practical than with heavier alternatives like aluminum or wood composite materials.