When choosing packaging and display materials for industrial applications, businesses often find themselves comparing fluted plastic sheets against traditional corrugated cardboard options. Both materials serve similar structural purposes, but their performance characteristics, durability, and cost-effectiveness vary significantly across different use cases. Understanding these differences becomes crucial for procurement managers, packaging engineers, and facility operators who need to make informed decisions that impact both operational efficiency and bottom-line results. The choice between these materials can influence everything from product protection during transit to long-term storage solutions and environmental sustainability goals.

Material Composition and Manufacturing Differences

Structural Design Fundamentals

The fundamental difference between these materials lies in their composition and manufacturing processes. Corrugated cardboard consists of multiple layers of paper-based materials, typically featuring a fluted inner core sandwiched between flat outer layers. This design creates air pockets that provide cushioning and insulation properties while maintaining relatively lightweight characteristics. The manufacturing process involves pressing recycled paper fibers through heated rollers and applying adhesives to bond the layers together.

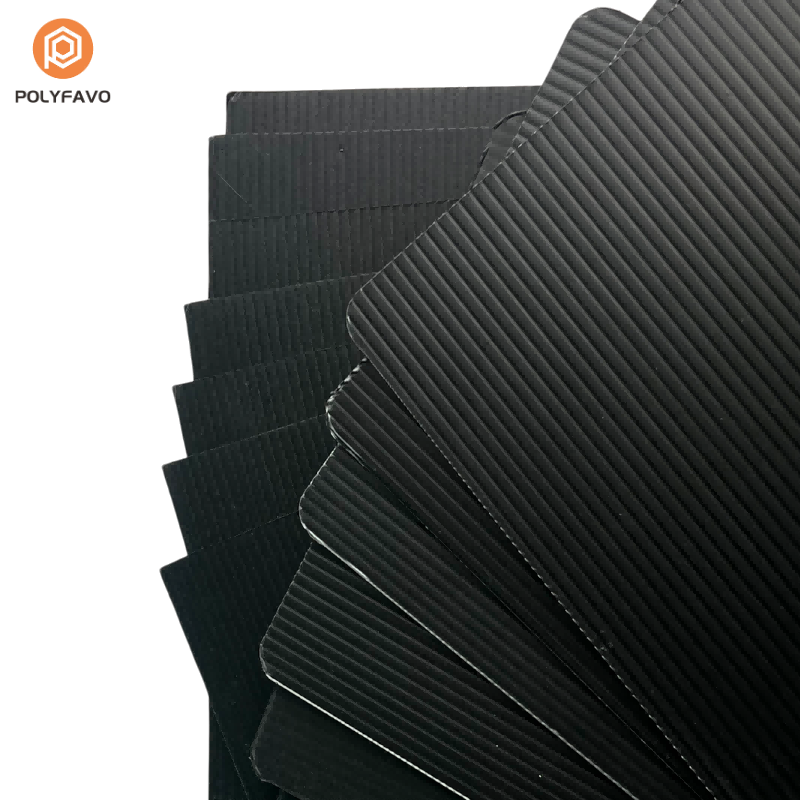

In contrast, fluted plastic sheets are manufactured through extrusion processes using thermoplastic materials such as polypropylene or polyethylene. The fluted structure is created by forcing molten plastic through specially designed dies that form parallel channels running along the length of the sheet. This process results in a hollow-core structure similar to corrugated cardboard but with significantly different performance characteristics due to the plastic composition.

Raw Material Properties

The raw materials used in each option contribute to their distinct performance profiles. Corrugated cardboard relies on cellulose fibers derived from wood pulp, which provides natural biodegradability but also creates vulnerability to moisture, chemicals, and biological degradation. The paper-based composition makes it susceptible to compression over time, especially in humid environments or under sustained loads.

Plastic fluted sheets utilize synthetic polymers that offer superior chemical resistance, moisture protection, and dimensional stability. These materials maintain their structural integrity across wider temperature ranges and resist degradation from UV exposure when properly formulated. The plastic composition also enables consistent performance characteristics throughout the material's service life, without the gradual weakening that affects paper-based alternatives.

Durability and Performance Characteristics

Environmental Resistance Factors

Environmental conditions play a crucial role in determining material performance over time. Corrugated cardboard demonstrates excellent performance in controlled indoor environments with stable temperature and humidity levels. However, exposure to moisture, temperature fluctuations, or chemical vapors can rapidly compromise its structural integrity and protective capabilities. The hygroscopic nature of paper fibers means that even moderate humidity increases can reduce compression strength and dimensional stability.

Fluted plastic sheets excel in challenging environmental conditions where cardboard would fail. Their non-porous surface resists moisture absorption, preventing swelling, warping, or delamination that commonly affects paper-based materials. Chemical resistance varies by polymer type, but most plastic sheets can withstand exposure to oils, solvents, and cleaning agents that would destroy cardboard alternatives. Temperature stability typically ranges from sub-zero to elevated temperatures without significant property changes.

Mechanical Strength and Load-Bearing Capacity

Load-bearing capacity represents another critical performance differentiator between these materials. Corrugated cardboard provides adequate strength for many packaging applications, with edge crush strength and burst strength specifications that meet standard shipping requirements. However, sustained loading or repeated handling cycles can cause compression set and permanent deformation, reducing protective capabilities over time.

The mechanical properties of fluted plastic sheets remain more consistent throughout their service life. Higher impact resistance and recovery from deformation make them suitable for reusable applications where cardboard would require frequent replacement. The plastic structure maintains its shape memory, returning to original dimensions after temporary loading, which proves valuable in applications requiring multiple use cycles.

Cost Analysis and Economic Considerations

Initial Investment and Procurement Costs

Initial material costs typically favor corrugated cardboard, especially for single-use applications or high-volume packaging requirements. The established manufacturing infrastructure and readily available raw materials keep cardboard prices competitive, particularly for standard sizes and specifications. Bulk purchasing agreements and regional supplier networks further reduce procurement costs for businesses with predictable volume requirements.

Fluted plastic sheets command higher initial purchase prices due to polymer costs and more complex manufacturing processes. However, this price differential must be evaluated against lifecycle costs and performance requirements rather than initial purchase price alone. Custom specifications, special additives for UV resistance or flame retardancy, and specialized polymer grades can significantly impact plastic sheet pricing structures.

Total Cost of Ownership Evaluation

Long-term cost analysis often reveals different economic conclusions than initial price comparisons suggest. Corrugated cardboard's lower upfront cost can be offset by replacement frequency, especially in applications involving moisture exposure, repeated handling, or extended storage periods. Transportation costs may also increase due to damage rates and the need for additional protective packaging in challenging environments.

The durability advantage of fluted plastic sheets translates into reduced replacement costs and lower total ownership expenses in many applications. Reusability factors can justify higher initial investments through extended service life and reduced waste disposal costs. Applications requiring frequent cleaning, sterilization, or exposure to harsh chemicals often demonstrate clear economic advantages for plastic alternatives despite higher initial costs.

Application-Specific Performance Comparison

Packaging and Shipping Applications

In traditional packaging and shipping scenarios, both materials serve similar functions with distinct advantages. Corrugated cardboard remains the standard choice for single-use shipping containers, retail packaging, and applications where disposal convenience outweighs durability requirements. Its printability and customization options make it ideal for branded packaging applications where visual presentation matters.

Fluted plastic sheets excel in specialized packaging applications requiring superior protection or reusability. Electronics packaging, pharmaceutical shipping containers, and hazardous material transport often justify the higher costs through enhanced protection and regulatory compliance capabilities. The ability to incorporate antistatic properties, barrier coatings, or specialized additives makes plastic sheets valuable for sensitive product applications.

Industrial and Construction Uses

Beyond packaging applications, both materials find uses in industrial and construction environments with varying success rates. Corrugated cardboard serves well as temporary protection during construction, paint masking applications, and short-term barrier installations. Its low cost and easy disposal make it practical for applications where contamination or damage is expected.

Industrial applications often favor fluted plastic sheets for their chemical resistance and durability characteristics. Temporary flooring protection, chemical containment barriers, and reusable separation panels demonstrate the value of plastic alternatives in demanding environments. The ability to clean and reuse these materials reduces waste generation and ongoing material costs in industrial settings.

Environmental Impact and Sustainability

Recycling and End-of-Life Considerations

Environmental considerations increasingly influence material selection decisions across industries. Corrugated cardboard offers clear advantages in biodegradability and established recycling infrastructure. Most regions have well-developed paper recycling systems that can process cardboard waste efficiently, contributing to circular economy principles and reducing landfill burden.

Plastic recycling presents more complex challenges, though opportunities exist for mechanical recycling of clean plastic sheets. The durability that makes fluted plastic sheets valuable in use also extends their environmental persistence if not properly managed at end-of-life. However, their extended service life and reusability can offset environmental impacts through reduced material consumption over time.

Carbon Footprint and Manufacturing Impact

Manufacturing processes contribute differently to overall environmental impact for each material type. Corrugated cardboard production typically involves lower energy requirements and utilizes renewable raw materials, resulting in lower carbon footprint per unit produced. The established recycling infrastructure also reduces virgin material requirements in many manufacturing operations.

Plastic sheet manufacturing requires higher energy inputs and relies on petroleum-based raw materials, creating larger initial carbon footprints. However, the extended service life and reduced replacement frequency can distribute these impacts over longer periods, potentially resulting in lower lifetime environmental costs for applications requiring durability and reusability characteristics.

FAQ

Which material offers better moisture resistance for outdoor applications

Fluted plastic sheets provide superior moisture resistance compared to corrugated cardboard for outdoor applications. The non-porous plastic surface prevents water absorption, maintaining structural integrity and dimensional stability even in wet conditions. Corrugated cardboard rapidly deteriorates when exposed to moisture, losing strength and protective capabilities.

Can both materials be customized for specific industrial requirements

Both materials offer customization options, though with different capabilities. Corrugated cardboard can be easily printed, die-cut, and formed into complex shapes at relatively low costs. Fluted plastic sheets can incorporate specialized additives like UV stabilizers, antistatic properties, or flame retardants, and can be thermoformed into three-dimensional shapes for specific applications.

How do transportation costs compare between these materials

Transportation costs depend on application requirements and damage rates. Corrugated cardboard typically weighs less, reducing shipping costs per unit, but may require additional protective packaging in challenging conditions. Fluted plastic sheets cost more to transport initially but their durability reduces damage rates and potential replacement shipments, often resulting in lower total transportation costs.

Which option provides better long-term value for reusable applications

Fluted plastic sheets typically provide better long-term value for reusable applications due to their durability and resistance to wear. While initial costs are higher, their ability to withstand multiple use cycles, cleaning processes, and environmental exposure often results in lower cost per use compared to repeatedly replacing corrugated cardboard materials.