The logistics industry continuously evolves to meet growing demands for efficient, cost-effective transportation and storage solutions. Among the innovative packaging technologies that have transformed modern supply chains, the pallet sleeve box stands out as a versatile and practical solution for businesses across various sectors. This specialized packaging system combines the stability of traditional pallets with the protective benefits of collapsible containers, offering unprecedented flexibility for warehousing, shipping, and inventory management operations.

Modern enterprises face mounting pressure to optimize their logistics operations while reducing environmental impact and operational costs. Traditional packaging methods often fall short when it comes to space utilization, durability, and sustainability requirements. The emergence of advanced pallet sleeve box systems addresses these challenges by providing a comprehensive solution that enhances operational efficiency while maintaining product integrity throughout the entire supply chain process.

Enhanced Space Utilization and Storage Efficiency

Maximized Warehouse Capacity

One of the most significant advantages of implementing pallet sleeve box systems lies in their exceptional space utilization capabilities. These innovative containers can be stacked to considerable heights while maintaining structural integrity, allowing warehouses to maximize their vertical storage capacity. Unlike traditional packaging methods that often leave unused space between containers, pallet sleeve boxes are designed to fit together seamlessly, eliminating wasted cubic footage in storage facilities.

The standardized dimensions of pallet sleeve box units ensure optimal compatibility with existing warehouse infrastructure, including racking systems, forklifts, and automated handling equipment. This compatibility translates into more efficient use of available floor space, enabling businesses to store larger quantities of inventory without expanding their physical facilities. The result is a significant reduction in storage costs per unit and improved inventory turnover rates.

Collapsible Design Benefits

When not in use, pallet sleeve box systems can be collapsed to a fraction of their operational size, dramatically reducing storage requirements for empty containers. This collapsible feature is particularly valuable for businesses that experience seasonal fluctuations in shipping volumes or need to transport empty containers back to distribution centers. The ability to fold down these containers results in substantial savings on return transportation costs and warehouse space allocation for empty packaging materials.

The collapsible nature of these systems also facilitates better inventory management of packaging supplies themselves. Warehouse managers can maintain adequate stock levels of containers without dedicating excessive space to empty packaging, allowing for more flexible allocation of storage areas based on actual product inventory needs rather than packaging requirements.

Superior Product Protection and Security

Robust Construction Materials

The construction of pallet sleeve box systems incorporates high-quality materials specifically engineered to withstand the rigors of modern logistics operations. These containers feature reinforced corners, impact-resistant walls, and secure locking mechanisms that provide superior protection against damage during handling, transportation, and storage. The robust design ensures that products remain safe from environmental factors such as moisture, dust, and temperature fluctuations.

Advanced manufacturing techniques used in producing pallet sleeve box units result in containers that maintain their structural integrity even under heavy loads and repeated use. The durability of these systems translates into extended service life, reducing the frequency of container replacement and associated costs. This longevity makes them an economically sound investment for businesses with high-volume shipping requirements.

Integrated Security Features

Security concerns are paramount in modern logistics operations, and pallet sleeve box systems address these challenges through integrated security features. Many models include tamper-evident closures, reinforced locking mechanisms, and options for security seals that provide clear indication of unauthorized access attempts. These security measures help protect valuable cargo during transit and storage, reducing losses due to theft or tampering.

The enclosed design of pallet sleeve box systems also provides protection against environmental contamination and accidental damage that could occur with open or partially covered shipping methods. This level of protection is particularly important for sensitive products such as pharmaceuticals, electronics, or food items that require maintained integrity throughout the supply chain.

Cost Reduction and Economic Benefits

Reduced Packaging Material Costs

The reusable nature of pallet sleeve box systems provides substantial cost savings compared to single-use packaging alternatives. While the initial investment may be higher than disposable options, the ability to use these containers repeatedly over extended periods results in significantly lower per-shipment packaging costs. Businesses typically recover their initial investment within months of implementation, after which the continued use generates ongoing savings.

The standardized design of pallet sleeve box units also reduces the need for various packaging sizes and types, simplifying procurement processes and reducing inventory costs for packaging materials. This standardization enables businesses to negotiate better pricing with suppliers due to higher volume purchases and reduces the complexity of managing multiple packaging SKUs in their operations.

Labor Efficiency Improvements

The user-friendly design of pallet sleeve box systems contributes to significant labor efficiency improvements in warehouse and distribution operations. Workers can quickly assemble and disassemble these containers without requiring specialized tools or extensive training, reducing the time spent on packaging preparation and breakdown activities. This efficiency translates into lower labor costs per shipment and improved productivity metrics.

The ergonomic design features incorporated into modern pallet sleeve box systems also reduce the physical strain on workers, potentially decreasing workplace injuries and associated costs. The lightweight materials and intuitive assembly mechanisms enable faster handling while maintaining safety standards, contributing to overall operational efficiency and employee satisfaction.

Environmental Sustainability Advantages

Reduced Waste Generation

Environmental sustainability has become a critical consideration for businesses across all industries, and pallet sleeve box systems offer significant advantages in this area. The reusable nature of these containers dramatically reduces packaging waste compared to single-use alternatives such as cardboard boxes or disposable plastic containers. This reduction in waste generation helps companies meet their sustainability goals while potentially avoiding waste disposal costs and environmental fees.

The long service life of pallet sleeve box units means that fewer containers need to be manufactured over time, reducing the overall environmental impact associated with production, transportation, and disposal of packaging materials. This extended lifecycle contributes to a more sustainable supply chain model that aligns with corporate social responsibility initiatives and environmental regulations.

Recyclable Materials and End-of-Life Management

Most pallet sleeve box systems are manufactured using recyclable materials, ensuring that even at the end of their service life, these containers can be processed into new products rather than ending up in landfills. This recyclability factor is increasingly important as businesses seek to minimize their environmental footprint and comply with evolving environmental regulations and customer expectations regarding sustainable practices.

The materials used in manufacturing pallet sleeve box units are often sourced from recycled content, creating a closed-loop system that further reduces environmental impact. This approach to material selection and end-of-life management demonstrates a commitment to circular economy principles and helps businesses achieve their sustainability targets while maintaining operational efficiency.

Versatility and Adaptability Across Industries

Multi-Industry Applications

The versatile design of pallet sleeve box systems makes them suitable for a wide range of industries and applications. From automotive parts and electronics to food and beverage distribution, these containers can accommodate diverse product types while maintaining their protective and efficiency benefits. This versatility allows businesses to standardize their packaging approach across different product lines, simplifying logistics operations and reducing complexity.

The ability to customize pallet sleeve box dimensions and features to meet specific industry requirements further enhances their applicability. Manufacturers can modify container heights, add ventilation features, or incorporate specialized closures to address unique product characteristics or regulatory requirements, making these systems adaptable to virtually any logistics application.

Integration with Existing Systems

One of the key advantages of pallet sleeve box systems is their compatibility with existing logistics infrastructure and equipment. These containers are designed to work seamlessly with standard pallet dimensions, forklift specifications, and warehouse racking systems, eliminating the need for costly infrastructure modifications when implementing this packaging solution.

The standardized footprint of pallet sleeve box units also ensures compatibility with transportation vehicles, including trucks, rail cars, and shipping containers. This compatibility maximizes loading efficiency and ensures that businesses can fully utilize available transportation capacity, resulting in lower shipping costs per unit and improved overall logistics efficiency.

Improved Supply Chain Visibility and Tracking

Enhanced Inventory Management

Modern pallet sleeve box systems can be equipped with tracking technologies such as RFID tags or barcode labels that enable real-time inventory monitoring throughout the supply chain. This enhanced visibility allows businesses to maintain accurate inventory records, reduce stock discrepancies, and improve overall supply chain efficiency. The ability to track containers and their contents in real-time also facilitates better demand forecasting and inventory planning.

The standardized nature of pallet sleeve box systems simplifies inventory counting and auditing processes, as containers can be easily identified and their contents verified through integrated tracking systems. This standardization reduces the likelihood of counting errors and improves the accuracy of inventory management systems, leading to better decision-making and reduced carrying costs.

Supply Chain Transparency

The use of pallet sleeve box systems with integrated tracking capabilities provides unprecedented transparency throughout the supply chain, enabling stakeholders to monitor shipment progress, identify potential delays, and proactively address issues before they impact customer satisfaction. This visibility is particularly valuable for time-sensitive shipments or high-value products that require close monitoring during transit.

Enhanced supply chain transparency also facilitates better communication between trading partners, as all parties can access real-time information about shipment status and location. This improved communication leads to more efficient coordination of logistics activities and reduces the administrative burden associated with tracking and tracing shipments through traditional methods.

FAQ

What is the typical lifespan of a pallet sleeve box system

A well-maintained pallet sleeve box system typically lasts between 5 to 10 years depending on usage frequency, handling practices, and environmental conditions. The robust construction materials and reinforced design features ensure extended service life even under demanding logistics operations. Regular inspection and proper maintenance can extend the lifespan further, making these systems a cost-effective long-term investment for businesses with ongoing shipping needs.

How do pallet sleeve boxes compare to traditional wooden crates in terms of performance

Pallet sleeve boxes offer several advantages over traditional wooden crates, including lighter weight, better moisture resistance, and consistent dimensions. Unlike wooden crates that can splinter, warp, or harbor pests, modern pallet sleeve box systems maintain their structural integrity and cleanliness throughout their service life. They also require no fumigation for international shipping and can be easily cleaned and sanitized, making them suitable for industries with strict hygiene requirements.

Can pallet sleeve box systems be customized for specific product requirements

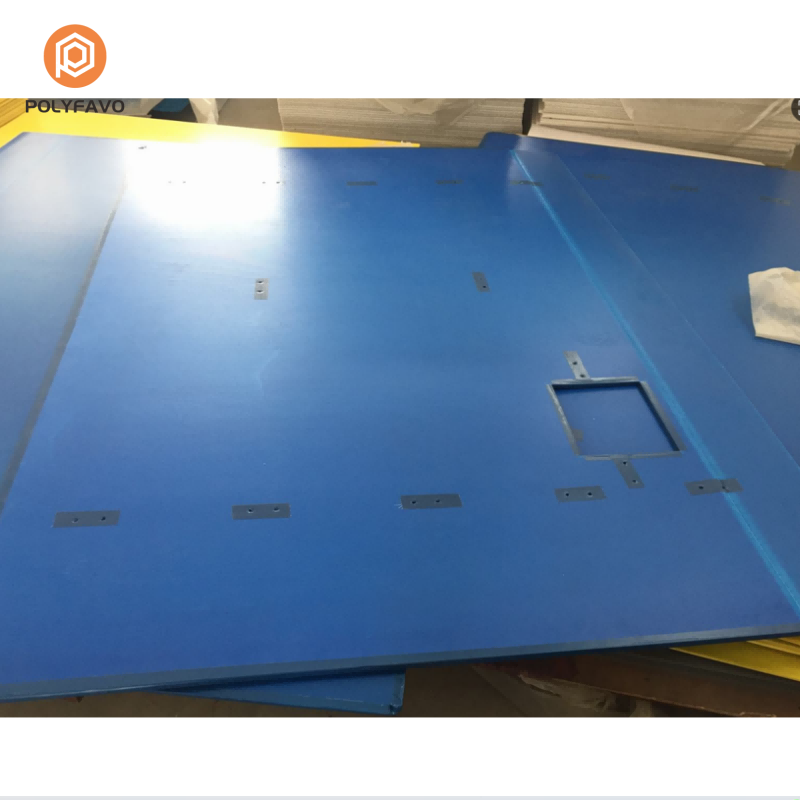

Yes, pallet sleeve box systems can be extensively customized to meet specific product and industry requirements. Customization options include adjustable heights, ventilation features, specialized closures, internal dividers, and various material specifications. Manufacturers can also incorporate company branding, specific color schemes, and specialized hardware to align with operational needs and corporate identity requirements.

What are the space savings when using collapsible pallet sleeve boxes

When collapsed, pallet sleeve box systems typically require only 10-15% of their operational volume, resulting in space savings of 85-90% for empty container storage. This dramatic reduction in storage requirements translates into significant cost savings for businesses that need to transport or store empty containers. The exact space savings depend on the specific design and configuration of the container system being used.