Maximizing Storage Performance in Moisture-Rich Environments

When it comes to warehouse storage solutions, the challenge of maintaining product integrity in high-humidity environments has long been a concern for logistics managers and facility operators. Corrugated plastic box solutions have emerged as a game-changing option, offering remarkable resilience against moisture while ensuring long-term storage efficiency. Understanding how these innovative storage solutions perform in demanding conditions is crucial for businesses looking to optimize their warehouse operations.

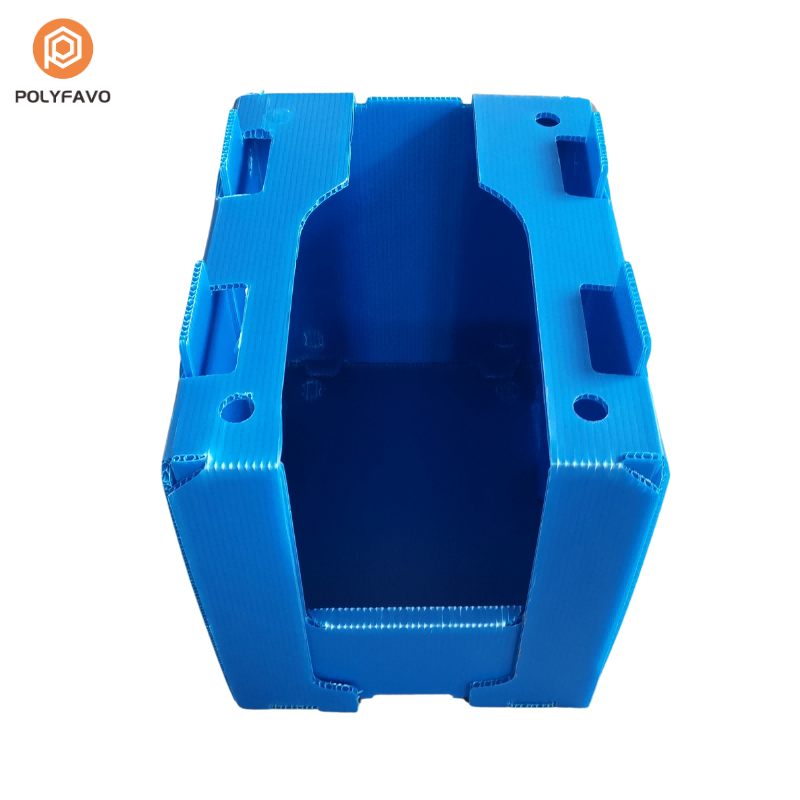

Understanding Corrugated Plastic Box Construction

Material Composition and Engineering

The unique structure of a corrugated plastic box combines multiple layers of polypropylene or polyethylene sheets, creating a durable yet lightweight storage solution. The corrugated design features parallel channels between two flat sheets, providing exceptional strength while maintaining flexibility. This engineering marvel results in containers that can withstand significant pressure and environmental stress without compromising structural integrity.

Advanced Manufacturing Techniques

Modern manufacturing processes employ sophisticated techniques to enhance the durability of corrugated plastic box units. Through precision molding and advanced bonding methods, manufacturers create seamless containers that resist water penetration and maintain their shape even under challenging conditions. The integration of UV stabilizers and anti-static additives further extends the lifespan of these storage solutions.

Moisture Resistance Properties

Water-Repellent Characteristics

Unlike traditional cardboard alternatives, corrugated plastic box solutions exhibit superior water-repellent properties. The non-porous nature of the plastic material prevents water absorption, ensuring that the structural integrity remains intact even when exposed to high humidity levels. This characteristic makes them particularly valuable in environments where moisture control presents ongoing challenges.

Vapor Barrier Performance

The inherent properties of corrugated plastic create an effective vapor barrier that protects stored contents from humidity damage. This barrier function prevents condensation from forming inside the container, maintaining optimal conditions for sensitive items. The material's ability to maintain consistent internal conditions makes it an ideal choice for long-term storage in variable humidity environments.

Performance in High-Humidity Settings

Temperature Fluctuation Response

Corrugated plastic box solutions demonstrate remarkable stability when faced with temperature variations common in high-humidity warehouses. The material maintains its structural properties across a wide temperature range, preventing warping or degradation that could compromise storage efficiency. This stability ensures consistent performance throughout seasonal changes and varying environmental conditions.

Long-term Durability Factors

The longevity of corrugated plastic box units in high-humidity environments is attributed to several key factors. The material's resistance to mold and mildew growth, combined with its ability to withstand repeated handling and stacking, ensures an extended service life. Additionally, the UV-resistant properties prevent degradation from exposure to artificial lighting or natural sunlight that may enter the warehouse environment.

Cost-Effectiveness and ROI

Initial Investment Considerations

While the upfront cost of corrugated plastic box solutions may be higher than traditional storage options, the long-term financial benefits become apparent through reduced replacement needs and enhanced protection of stored goods. The durability factor translates into fewer replacement cycles, effectively lowering the total cost of ownership over time.

Maintenance and Replacement Analysis

The minimal maintenance requirements of corrugated plastic box units contribute significantly to their cost-effectiveness. Simple cleaning procedures and occasional inspections are typically sufficient to maintain optimal performance. The extended lifespan of these containers, often exceeding several years in high-humidity conditions, provides substantial return on investment through reduced replacement costs and improved inventory protection.

Environmental Impact and Sustainability

Recyclability and Material Recovery

Modern corrugated plastic box solutions align with environmental sustainability goals through their recyclability. The materials can be effectively processed and repurposed at the end of their service life, reducing environmental impact. Many manufacturers now incorporate recycled content in their production processes, further enhancing the ecological benefits of these storage solutions.

Energy Efficiency in Production

The manufacturing process of corrugated plastic box units has evolved to minimize energy consumption while maximizing material efficiency. Advanced production techniques reduce waste and optimize resource utilization, contributing to a smaller carbon footprint compared to traditional storage container manufacturing methods.

Implementation Best Practices

Storage Configuration Guidelines

Maximizing the benefits of corrugated plastic box solutions requires careful attention to storage configuration. Proper stacking techniques, adequate ventilation spacing, and strategic placement within the warehouse environment ensure optimal performance and longevity. Understanding load capacity limits and implementing appropriate handling procedures helps maintain structural integrity over time.

Monitoring and Maintenance Protocols

Regular monitoring of storage conditions and container performance helps identify potential issues before they impact operations. Establishing clear maintenance schedules and inspection protocols ensures consistent performance in high-humidity environments. Training warehouse staff in proper handling and maintenance procedures further extends the service life of these storage solutions.

Frequently Asked Questions

How long can corrugated plastic boxes last in high-humidity conditions?

Under proper maintenance and usage conditions, corrugated plastic box solutions typically last 5-7 years in high-humidity environments, significantly outlasting traditional storage alternatives. However, actual lifespan can vary based on specific environmental conditions and handling practices.

What temperature range can these storage solutions withstand?

Corrugated plastic box units maintain their structural integrity across a temperature range of -20°C to 60°C (-4°F to 140°F), making them suitable for various warehouse environments and seasonal conditions.

Are special cleaning procedures required for maintenance?

Basic cleaning with mild soap and water is typically sufficient for maintaining corrugated plastic box units. Avoid harsh chemical cleaners that might compromise the material's integrity. Regular inspection and prompt attention to any damage ensure optimal performance and longevity.

Table of Contents

- Maximizing Storage Performance in Moisture-Rich Environments

- Understanding Corrugated Plastic Box Construction

- Moisture Resistance Properties

- Performance in High-Humidity Settings

- Cost-Effectiveness and ROI

- Environmental Impact and Sustainability

- Implementation Best Practices

- Frequently Asked Questions