Understanding the Revolutionary Pallet Sleeve Box System

In the world of logistics and supply chain management, innovation continues to reshape how we handle, store, and transport goods. The pallet sleeve box represents one such groundbreaking solution that has transformed the packaging industry. This versatile packaging system combines the stability of traditional pallets with the protection of sleeve-style containers, creating an efficient and sustainable solution for modern shipping needs.

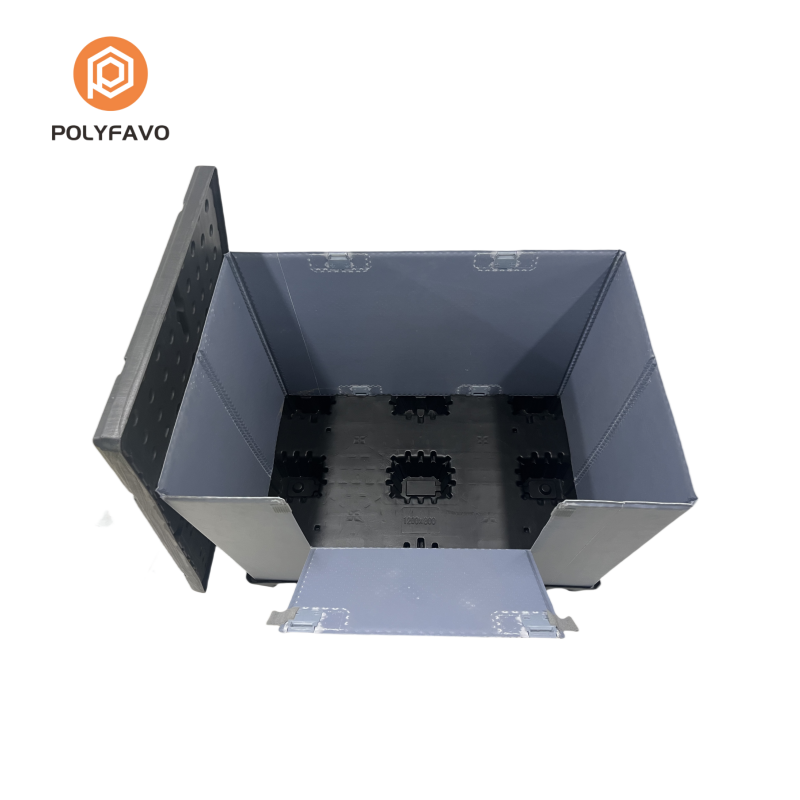

A pallet sleeve box consists of a bottom pallet, collapsible sleeve walls, and a top cover that work together seamlessly to protect and transport goods. This innovative design has gained significant traction across various industries, from automotive parts to consumer goods, offering unprecedented flexibility and protection during storage and transit.

Core Components and Design Features

Essential Elements of Pallet Sleeve Box Construction

The foundation of every pallet sleeve box starts with a robust pallet base, typically made from wood, plastic, or composite materials. The sleeve component consists of durable corrugated cardboard or plastic panels that can be easily erected or collapsed as needed. The top cover completes the assembly, providing full protection from all sides.

Advanced design features often include reinforced corners, interlocking mechanisms, and weather-resistant materials. These elements ensure the structural integrity of the pallet sleeve box while maximizing its protective capabilities during transportation and storage.

Material Options and Specifications

Modern pallet sleeve boxes are available in various materials, each offering unique advantages. Corrugated cardboard sleeves provide cost-effective and recyclable solutions, while plastic variants offer enhanced durability and weather resistance. Some manufacturers even produce hybrid designs that combine different materials to achieve optimal performance characteristics.

The choice of materials significantly impacts the pallet sleeve box's weight capacity, stackability, and overall lifespan. High-quality materials ensure repeated use while maintaining structural integrity throughout multiple logistics cycles.

Benefits and Applications

Operational Advantages

The pallet sleeve box system offers numerous operational benefits that make it an attractive choice for modern logistics operations. Its collapsible design significantly reduces storage space requirements when not in use, leading to substantial cost savings in warehouse management. The system's modularity allows for quick assembly and disassembly, improving handling efficiency and reducing labor costs.

These containers also excel in protecting goods during transit, with their full-enclosure design minimizing product damage and loss. The standardized dimensions ensure optimal space utilization in trucks and storage facilities, maximizing logistics efficiency.

Industry-Specific Applications

Different sectors leverage pallet sleeve boxes in unique ways to meet their specific requirements. The automotive industry uses them extensively for transporting sensitive components, while the retail sector benefits from their easy-to-handle design for store deliveries. Food and beverage companies appreciate their ability to maintain product integrity during distribution.

The pharmaceutical industry particularly values pallet sleeve boxes for their cleanliness and ability to maintain controlled environments. Electronics manufacturers rely on them for their anti-static properties and superior protection capabilities.

Environmental Impact and Sustainability

Eco-Friendly Aspects

The environmental benefits of pallet sleeve boxes align perfectly with modern sustainability goals. Their reusable nature significantly reduces packaging waste compared to single-use alternatives. When made from recyclable materials, these containers contribute to circular economy initiatives, helping companies meet their environmental responsibilities.

The reduced storage space requirements for collapsed sleeves also mean fewer transportation movements for empty returns, leading to a smaller carbon footprint. Many manufacturers now offer biodegradable options, further enhancing the environmental credentials of this packaging solution.

Long-term Sustainability Benefits

Implementing pallet sleeve boxes as part of a comprehensive packaging strategy can deliver substantial long-term environmental benefits. Their durability ensures extended service life, reducing the need for frequent replacements. The standardized dimensions optimize loading efficiency, potentially reducing the number of required shipments and associated emissions.

Companies that adopt pallet sleeve boxes often report significant reductions in their overall packaging waste and improved sustainability metrics. This alignment with environmental goals can enhance brand reputation and meet increasingly stringent regulatory requirements.

Cost Implications and ROI

Initial Investment Considerations

While the upfront cost of pallet sleeve boxes may be higher than traditional single-use packaging, the long-term financial benefits often justify the investment. The initial expenditure covers high-quality materials and construction that ensure durability and reusability, leading to cost savings over time.

Companies should consider factors such as expected usage frequency, handling conditions, and specific protection requirements when evaluating the investment. The cost analysis should also account for potential reductions in product damage and improved logistics efficiency.

Long-term Financial Benefits

The return on investment for pallet sleeve boxes typically becomes apparent within the first year of implementation. Reduced packaging waste, lower storage costs, and decreased product damage contribute to significant cost savings. The system's efficiency in loading and unloading operations can also lead to labor cost reductions.

Additional financial benefits include lower transportation costs due to optimized space utilization and reduced need for replacement packaging. Many companies report overall packaging cost reductions of 20-30% after switching to pallet sleeve boxes.

Frequently Asked Questions

How long do pallet sleeve boxes typically last?

The lifespan of a pallet sleeve box depends on usage patterns and handling conditions but typically ranges from 30 to 50 trips when properly maintained. High-quality materials and careful handling can extend this lifespan significantly.

Can pallet sleeve boxes be customized for specific products?

Yes, pallet sleeve boxes can be customized in terms of dimensions, materials, and internal configurations to accommodate specific product requirements. Many manufacturers offer bespoke solutions to meet unique industry needs.

What maintenance is required for pallet sleeve boxes?

Regular maintenance typically involves inspection for damage, cleaning as needed, and proper storage when not in use. It's important to keep the components dry and store collapsed sleeves in appropriate conditions to maximize their lifespan.

Are pallet sleeve boxes suitable for international shipping?

Yes, pallet sleeve boxes are widely used in international shipping due to their compliance with global shipping standards and excellent protection capabilities. They often meet ISPM 15 regulations when constructed with appropriate materials.