Revolutionizing Supply Chain Sustainability with Reusable Packaging Solutions

The evolution of modern supply chains demands innovative solutions that balance efficiency with environmental responsibility. PP honeycomb plastic boxes have emerged as a game-changing solution, offering durability, cost-effectiveness, and sustainable benefits for businesses committed to circular economy principles. These revolutionary containers are transforming how companies approach their logistics operations while significantly reducing their environmental footprint.

As industries worldwide pivot towards more sustainable practices, the adoption of pp honeycomb plastic boxes in closed-loop supply chains represents a significant step forward. These versatile containers not only optimize storage and transportation but also demonstrate a commitment to environmental stewardship that resonates with eco-conscious consumers and stakeholders.

The Fundamental Advantages of PP Honeycomb Technology

Superior Structural Design and Material Properties

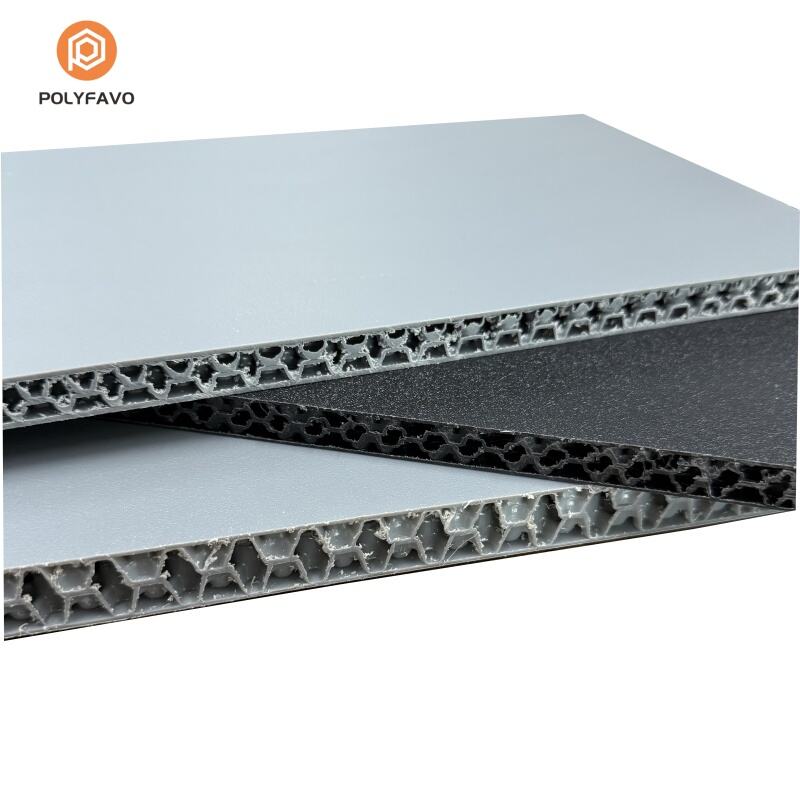

PP honeycomb plastic boxes feature an innovative hexagonal cell structure that provides exceptional strength-to-weight ratio. This unique design enables the boxes to withstand substantial loads while remaining lightweight and easy to handle. The polypropylene material offers excellent chemical resistance, making these containers suitable for various industrial applications.

The structural integrity of pp honeycomb plastic boxes is further enhanced by their impact-resistant nature. Unlike traditional packaging solutions, these boxes can absorb shock and maintain their shape under challenging conditions, ensuring the safety of transported goods while extending the container's useful life.

Environmental and Economic Benefits

The reusability factor of pp honeycomb plastic boxes delivers significant environmental advantages. Each container can complete multiple supply chain cycles, dramatically reducing the need for single-use packaging materials. This translates to decreased waste generation and lower carbon emissions associated with packaging production.

From an economic perspective, the initial investment in pp honeycomb plastic boxes yields substantial long-term savings. Companies can eliminate recurring expenditure on disposable packaging while minimizing product damage during transit. The lightweight nature of these containers also contributes to reduced transportation costs and fuel consumption.

Implementing Closed-Loop Supply Chain Systems

Strategic Planning and Infrastructure Development

Successful implementation of pp honeycomb plastic boxes in closed-loop systems requires careful planning and robust infrastructure. Organizations must establish efficient tracking systems, maintenance protocols, and return logistics networks. This includes developing partnerships with suppliers and customers to ensure smooth container circulation.

Investment in appropriate cleaning and sanitization facilities is crucial for maintaining the boxes in optimal condition. Companies should also consider storage requirements and handling equipment compatibility when integrating these containers into their existing operations.

Training and Process Optimization

Employee training plays a vital role in maximizing the benefits of pp honeycomb plastic boxes. Staff must understand proper handling techniques, inspection procedures, and maintenance requirements. Regular training sessions ensure consistent performance and help prevent damage to both containers and contents.

Process optimization involves continuous monitoring and adjustment of supply chain operations. This includes analyzing usage patterns, identifying bottlenecks, and implementing improvements to enhance container turnover rates and reduce cycle times.

Maintaining and Extending Container Lifespan

Regular Inspection and Maintenance Protocols

Establishing systematic inspection procedures helps identify potential issues before they affect performance. Regular checks should focus on structural integrity, cleanliness, and any signs of wear. Prompt repairs or replacement of damaged components ensure continued reliability and safety.

Maintenance schedules should account for usage frequency and environmental conditions. Companies operating in harsh environments may need more frequent inspections and maintenance interventions to preserve the functionality of their pp honeycomb plastic boxes.

Cleaning and Sanitization Standards

Maintaining high hygiene standards is essential, particularly in industries handling sensitive products. Proper cleaning protocols should be established based on specific industry requirements and product characteristics. The chemical resistance of pp honeycomb plastic boxes allows for the use of various cleaning agents without compromising structural integrity.

Documentation of cleaning procedures and regular audits ensure compliance with quality standards and regulatory requirements. This systematic approach helps maintain product safety and extends the useful life of the containers.

Future Trends and Innovation Opportunities

Technology Integration and Smart Packaging

The future of pp honeycomb plastic boxes includes integration with smart technologies such as RFID tags and IoT sensors. These innovations enable real-time tracking, condition monitoring, and automated inventory management. Enhanced data collection and analysis capabilities help optimize container utilization and supply chain efficiency.

Emerging technologies may also lead to improvements in material properties and design features. Research continues into enhancing durability, reducing weight, and incorporating sustainable materials while maintaining the core benefits of pp honeycomb construction.

Expanding Applications and Market Growth

As awareness of sustainable packaging solutions grows, pp honeycomb plastic boxes are finding new applications across diverse industries. From automotive and electronics to food and pharmaceutical sectors, these containers offer versatile solutions for various supply chain challenges.

Market expansion is driven by increasing environmental regulations and corporate sustainability goals. Companies investing in pp honeycomb plastic boxes position themselves advantageously for future growth while contributing to global sustainability efforts.

Frequently Asked Questions

What makes pp honeycomb plastic boxes more sustainable than traditional packaging?

PP honeycomb plastic boxes offer superior sustainability through their reusability, durability, and reduced material waste. Their long lifespan and ability to be recycled at end-of-life make them significantly more environmentally friendly than single-use alternatives.

How can businesses calculate the return on investment for implementing pp honeycomb plastic boxes?

ROI calculations should consider initial purchase costs, expected lifespan, reduction in packaging waste, decreased transportation costs, and lower product damage rates. Most organizations see positive returns within 12-18 months of implementation.

What are the key considerations for maintaining pp honeycomb plastic boxes in optimal condition?

Regular inspection, proper cleaning protocols, careful handling procedures, and scheduled maintenance are essential. Additionally, implementing tracking systems and training staff in proper usage helps maximize container lifespan and performance.