Understanding the Revolutionary PP Honeycomb Technology

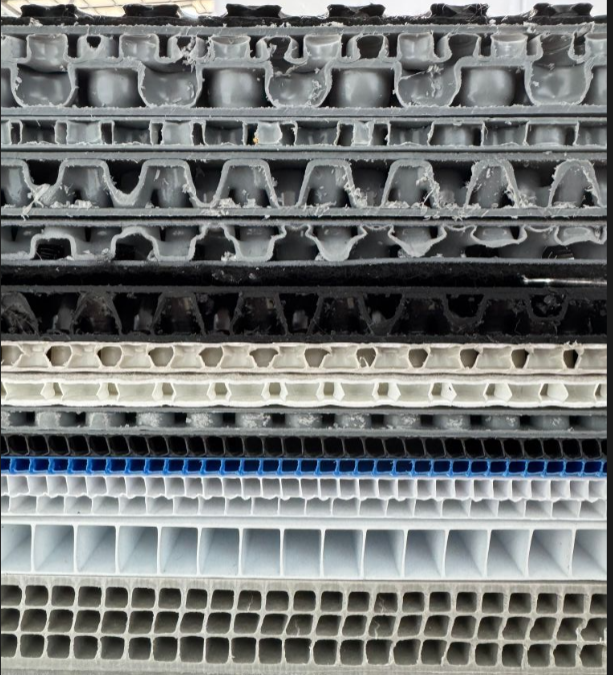

PP honeycomb board represents a groundbreaking advancement in sustainable packaging and construction materials. This innovative material combines lightweight properties with exceptional strength, making it an increasingly popular choice across various industries. Its unique hexagonal cell structure, inspired by nature's own architectural marvel - the honeycomb - delivers remarkable performance while maintaining eco-friendly credentials.

The manufacturing process of PP honeycomb board involves extruding polypropylene into a distinctive honeycomb core, which is then sandwiched between solid PP sheets. This ingenious design creates a material that boasts an impressive strength-to-weight ratio while utilizing minimal raw materials. As businesses worldwide seek sustainable alternatives to traditional materials, PP honeycomb board emerges as a compelling solution.

Key Features and Benefits of PP Honeycomb Board

Superior Structural Properties

The inherent design of PP honeycomb board provides exceptional compression strength and impact resistance. The hexagonal cell structure distributes forces evenly across the material, preventing localized stress concentrations. This unique characteristic makes it particularly suitable for heavy-duty applications where traditional materials might fail.

Moreover, the board's lightweight nature doesn't compromise its structural integrity. In fact, PP honeycomb board can support substantial loads while maintaining its shape and form, making it an ideal choice for applications requiring both strength and minimal weight.

Environmental Advantages

PP honeycomb board stands out for its impressive environmental credentials. The material is fully recyclable, contributing to circular economy initiatives. Its production requires significantly less raw material compared to solid boards, reducing the overall carbon footprint of manufacturing processes.

The lightweight nature of PP honeycomb board also translates into reduced transportation costs and lower fuel consumption during shipping, further minimizing environmental impact. Additionally, its durability means longer service life, reducing the need for frequent replacements and ultimately decreasing waste generation.

Applications Across Industries

Packaging Solutions

In the packaging industry, PP honeycomb board has revolutionized how products are protected during transit. Its superior shock absorption properties make it perfect for packaging delicate electronics, automotive parts, and industrial equipment. The material's moisture resistance adds another layer of protection, ensuring goods arrive in pristine condition regardless of environmental conditions.

Many companies have adopted PP honeycomb board for creating custom packaging solutions, finding it particularly effective for items requiring specific dimensional stability and impact protection. The material's ability to be easily cut and shaped allows for precise, tailored packaging designs that maximize protection while minimizing space utilization.

Construction and Interior Design

The construction sector has embraced PP honeycomb board for its versatility and performance characteristics. From temporary walls and partitions to furniture components and display units, the material offers architects and designers new possibilities in creating lightweight yet durable structures.

Interior designers particularly appreciate the material's smooth surface finish and printability, allowing for creative applications in retail displays, exhibition stands, and decorative panels. The board's excellent sound dampening properties make it a popular choice for creating acoustic barriers in office environments.

Installation and Handling Guidelines

Proper Storage and Preparation

To maintain the optimal performance of PP honeycomb board, proper storage conditions are essential. The material should be kept in a dry, covered area away from direct sunlight and extreme temperatures. Before installation, it's recommended to allow the board to acclimate to the installation environment for at least 24 hours.

Handling should be done with care, although the material is quite resilient. Clean gloves should be used to prevent surface contamination, and boards should be carried vertically to prevent unnecessary flexing. When cutting or modifying the board, appropriate tools and safety equipment should be utilized.

Installation Techniques

Professional installation of PP honeycomb board requires attention to detail and proper technique. The material can be cut using standard woodworking tools, though specialized blades often provide cleaner edges. When joining panels, various adhesives and mechanical fasteners can be used, depending on the specific application requirements.

For optimal results, it's crucial to follow manufacturer guidelines regarding spacing, support requirements, and fixing methods. Temperature fluctuations should be considered during installation, as the material may expand or contract slightly with significant temperature changes

Maintenance and Longevity

Cleaning and Care

One of the major advantages of PP honeycomb board is its low maintenance requirements. Regular cleaning can be accomplished using mild soap and water, with no need for harsh chemicals or specialized cleaning agents. The non-porous surface prevents the absorption of liquids and makes stain removal straightforward.

For more stubborn marks or commercial environments, professional cleaning solutions designed for polypropylene surfaces can be used. It's important to avoid abrasive cleaners or tools that might scratch or damage the surface finish.

Long-term Performance

PP honeycomb board demonstrates excellent longevity when properly maintained. The material resists degradation from UV exposure and maintains its structural integrity even after years of use. Regular inspections can help identify any potential issues early, though problems are rare due to the material's inherent durability.

Many installations have shown minimal signs of wear after decades of service, proving the material's long-term value proposition. This durability, combined with its low maintenance requirements, makes PP honeycomb board a cost-effective choice for many applications.

Frequently Asked Questions

What makes PP honeycomb board different from traditional materials?

PP honeycomb board distinguishes itself through its unique combination of lightweight properties, high strength, and environmental sustainability. Its hexagonal cell structure provides superior strength-to-weight ratio compared to solid boards, while using less material and being fully recyclable.

How weather-resistant is PP honeycomb board?

PP honeycomb board exhibits excellent weather resistance properties. It's moisture-resistant, UV-stable, and can withstand various temperature conditions without degradation. However, for outdoor applications, specific grades designed for exterior use should be selected.

What are the maximum dimensions available for PP honeycomb board?

Standard PP honeycomb board typically comes in sheets up to 2.4 x 1.2 meters, though custom sizes can be manufactured for specific applications. The thickness can range from 2mm to 50mm, depending on the intended use and structural requirements.

Can PP honeycomb board be recycled?

Yes, PP honeycomb board is fully recyclable. Being made from polypropylene, it can be processed through standard plastic recycling streams. This makes it an environmentally responsible choice for businesses committed to sustainability goals.