Pioneering Innovation in PP Honeycomb Board Manufacturing Technology

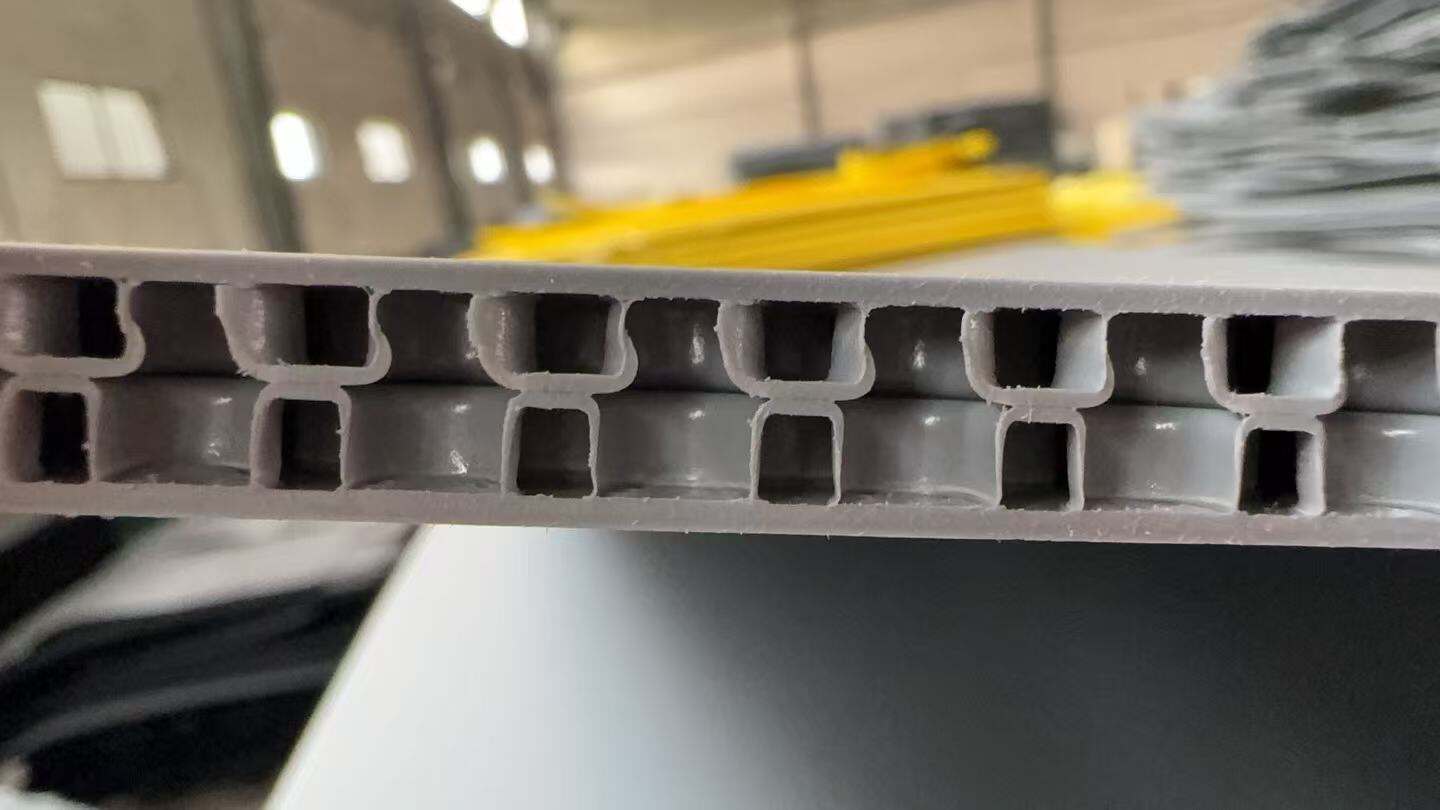

In 2025, Zhongcheng Qingdao New Material unveils China's first dual honeycomb machine. This revolutionary equipment marks a significant milestone in the advancement of pp honeycomb board production technology, setting new standards for efficiency and strength in the industry.

The introduction of this state-of-the-art dual honeycomb machine represents a leap forward in manufacturing capabilities, offering unprecedented production capacity and superior quality control. As global demand for honeycomb structures continues to rise across various sectors, this innovation positions China at the forefront of pp honeycomb board manufacturing technology.

Technical Excellence and Manufacturing Capabilities

Advanced Dual Processing System

The dual honeycomb machine incorporates cutting-edge technology that enables simultaneous processing of double honeycomb cores. The system's sophisticated control mechanisms ensure precise synchronization between both processing units, resulting in uniform cell structure and dimensional accuracy.

Enhanced with automated monitoring systems, the machine continuously adjusts parameters to optimize performance and maintain product consistency. This level of technical sophistication represents a significant advancement over traditional single-core processing methods.

Precision Engineering and Quality Control

At the heart of this innovative machine lies a meticulously engineered control system that maintains exact specifications throughout the production process. The integrated quality control mechanisms monitor critical parameters such as cell size, wall thickness, and overall structural integrity in real-time.

Advanced sensors and diagnostic tools provide immediate feedback, allowing operators to make precise adjustments when necessary. This comprehensive approach to quality assurance ensures that every honeycomb core meets stringent industry standards.

Production Efficiency and Economic Impact

Streamlined Manufacturing Process

The dual honeycomb machine's innovative design dramatically reduces production time while optimizing resource utilization. By processing two cores simultaneously, manufacturers can achieve significantly higher output rates without compromising on quality. This enhanced efficiency translates to reduced operational costs and improved market competitiveness.

The system's automated features minimize manual intervention, reducing labor requirements and human error potential. This optimization of resources contributes to a more sustainable and economical manufacturing process.

Market Advantages and Industry Leadership

Zhongcheng Qingdao New Material's breakthrough in dual honeycomb technology positions the company as an industry leader in advanced manufacturing. The increased production capacity enables better response to market demands while maintaining competitive pricing structures.

This technological advancement creates new opportunities for industries requiring honeycomb materials, from aerospace applications to automotive components. The improved efficiency and quality control capabilities provide a significant competitive advantage in the global market.

Environmental Sustainability and Future Development

Eco-friendly Manufacturing Solutions

The dual honeycomb machine incorporates environmentally conscious design elements that reduce energy consumption and material waste. The optimized processing system ensures maximum material utilization, contributing to sustainable manufacturing practices.

Advanced resource management features and energy-efficient components align with global sustainability initiatives, making this technology particularly attractive to environmentally conscious industries.

Innovation Roadmap and Future Capabilities

Zhongcheng Qingdao New Material continues to invest in research and development, focusing on further enhancing the dual honeycomb machine's capabilities. Planned upgrades include integration of artificial intelligence for predictive maintenance and even greater automation of quality control processes.

The company's commitment to technological advancement suggests future iterations will offer even more sophisticated features and improved performance metrics, maintaining China's competitive edge in honeycomb manufacturing technology.

Frequently Asked Questions

What are the primary advantages of the dual honeycomb machine over traditional systems?

The dual honeycomb machine offers doubled production capacity, enhanced precision control, and improved resource efficiency. It features simultaneous processing of two cores, advanced quality monitoring systems, and reduced operational costs compared to conventional single-core machines.

How does this technology impact product quality and consistency?

The machine's sophisticated control systems and real-time monitoring capabilities ensure consistent cell structure, precise dimensional accuracy, and superior overall quality. Automated quality control mechanisms maintain strict standards throughout the production process.

What industries can benefit from this advanced manufacturing technology?

This technology serves various sectors including aerospace, automotive, construction, and marine industries. Any application requiring high-quality honeycomb structures can benefit from the improved efficiency and precision offered by the dual honeycomb machine.

What future developments can we expect in honeycomb manufacturing technology?

Future developments will likely include AI integration, enhanced automation capabilities, and even more sophisticated quality control systems. Continued research and development efforts focus on improving efficiency, sustainability, and production capabilities to meet evolving industry demands.

Table of Contents

- Pioneering Innovation in PP Honeycomb Board Manufacturing Technology

- Technical Excellence and Manufacturing Capabilities

- Production Efficiency and Economic Impact

- Environmental Sustainability and Future Development

-

Frequently Asked Questions

- What are the primary advantages of the dual honeycomb machine over traditional systems?

- How does this technology impact product quality and consistency?

- What industries can benefit from this advanced manufacturing technology?

- What future developments can we expect in honeycomb manufacturing technology?