Z Fold Pallet Sleeve

These sleeves are designed to provide protective, reusable containers for palletized goods. They're used in logistics and warehousing to efficiently transport and store products.

- Overview

- Recommended Products

These sleeves are designed to provide protective, reusable containers for palletized goods. They're used in logistics and warehousing to efficiently transport and store products.

"Z Fold" Design:

The "Z fold" refers to a particular way the sleeve is designed to fold when not in use. This folding pattern is optimized for space efficiency during return trips or storage.

This is in contrast to other folding patterns, like the "M fold". The difference in the folding pattern is to allow for differing ratios of the containers height, to the width and length of the pallet.

Materials and Features:

These sleeves are typically made from durable materials like polypropylene.

They often feature:

Collapsible design for space-saving.

Robust construction to protect goods from damage.

Customizable sizes and features.

In essence, a Z Fold Pallet Sleeve is a reusable, collapsible container that enhances the efficiency and protection of palletized goods during shipping and storage.

Core Function:

A Z Fold Pallet Sleeve is a reusable, collapsible container designed to protect and contain goods that are palletized for shipping or storage. It forms the vertical walls of a box, which, when combined with a pallet base and a top lid, creates a complete, protective container.

"Z Fold" Specifics:

The "Z fold" designation refers to the specific folding pattern of the sleeve when it's collapsed. This pattern is engineered to maximize space efficiency during return trips or storage when the sleeve is not in use.

The Z fold pattern is often utilized when the height of the sleeve is greater than the internal width of the pallet, but less than the internal length. This differs from other folding patterns, like the "M fold", that are used in different dimensional situations.

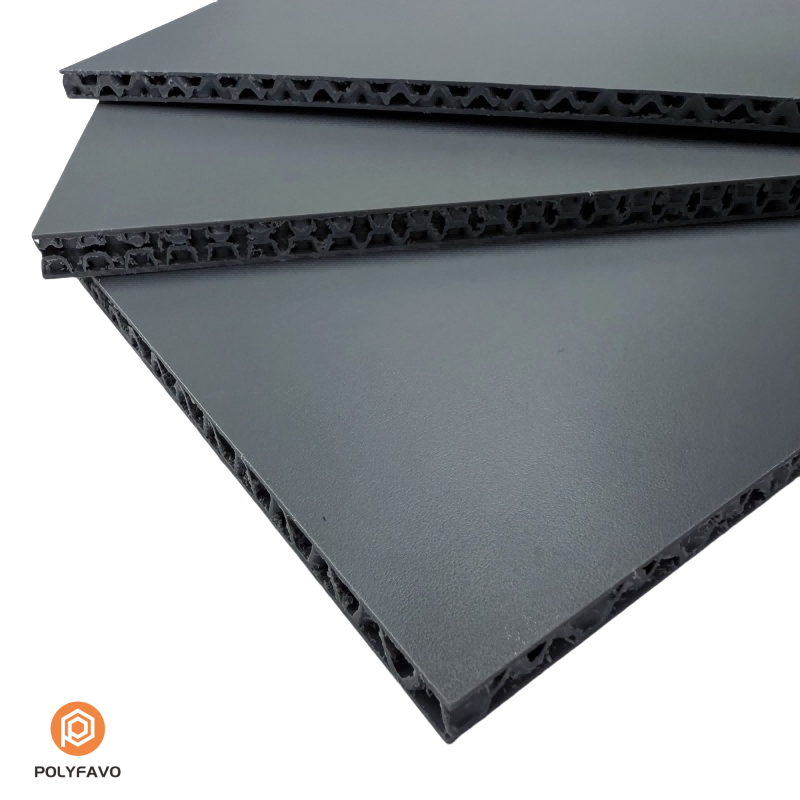

Material and Construction:

● Polypropylene:

A common material is polypropylene, a durable and resilient plastic. This material offers resistance to moisture, chemicals, and impacts.

Often, polypropylene honeycomb structured sheets are used to give high strength, with low weight.

● Components:

Sleeve: The main body of the container, designed to fold in a "Z" pattern.

Pallet Base: A sturdy base, typically made of plastic or wood, that supports the weight of the goods.

Top Lid: A protective lid that covers the top of the container, allowing for stacking.

Key Features and Benefits:

● Reusability:

Designed for multiple uses, reducing packaging waste and costs.

● Collapsibility:

The "Z fold" design allows for efficient storage and return logistics.

● Protection:

Provides a robust barrier against dust, moisture, and physical damage.

● Customization:

Sizes, materials, and features can be tailored to specific requirements.

Additions such as access doors, or custom printing are often available.

● Space Efficiency:

Reduces storage space when not in use, and reduces transport space when returning empty.

● Durability:

Materials used are designed to withstand repeated use in logistical environments.

Applications:

● Automotive industry (parts transportation)

● Manufacturing and distribution

● Electronics industry

● Food and beverage industry

● Any industry that moves bulk goods on pallets.

In essence, a Z Fold Pallet Sleeve is a critical component in modern logistics, offering a sustainable and efficient solution for the transportation and storage of goods.

Product parameter list

Product Name |

Z Fold Pallet Sleeve |

Brand |

POLYFAVO |

Style |

Foldable Sleeve Pack |

Size |

1200mm x 1000mm |

Height |

860/1000/1640mm/ custom size |

Weight |

27.5kg |

Sleeve Pack Thickness |

8-12mm |

Litres |

860 |

Recycled Plastic |

No |

Volume (L) |

885L |

Material |

100% Recycled HDPE Base (Lid and Pallet) , and 100% virgin PP sleeve - Overall 67% recycled |

|

Can be printed with your branding

|

Yes |

Type |

Solid |

Printing |

On demand |

|

External Length (mm)

|

Lid/Pallet: 700-1470mm Sleeve pack: 600-1430mm |

External Width (mm) |

Lid/Pallet 400-1150mm Sleeve pack: 360-1110mm |

Exernal height |

500-1200mm |

|

Folded Height (mm)

|

229mm |

|

Trailer/Truck Quantity

|

52 Full / 286 Folded |

|

Max Load per Box

|

500kg (Stacked 2:1) |

|

Pallet Stack Quantity

|

11 |

Pallet type |

9 feet, closed pallet deck |

|

Static (kg)

|

1000kg |

|

Dynamic (kg)

|

500kg |

Max load per box (kg) |

500kg |

Max stack load (kg) |

1000kg |

Optional features |

Pallet/Sleeve locks (Pallet interlocks with lid to keep stacked containers stable.) Sliding tabs snap into place securing sleeve, pallet and lid. Handles |

|

Foldable

|

Yes |

|

Rackable

|

No |

Base Configuration |

On nine feet |

Stocked color |

Grey, Black |

Available in other colors |

No |

Stacking layer |

1+2 |

Lid |

Included |

Features |

● Thermoformed plastic 4-way entry pallet and lid. ● ①Closed base and slides with drop door and lid②Two handles ● The groove design of the lids ensures stable stacking and is not easy to fall off. ● Up to 80% less volume on the return cycle ● More than 70% lighter than traditional pallet cages ● 100% recyclable ● Stackable ● Environmentally friendly ● Nestable ● Foldable, high folding ratio ● 100% recyclable ● Does not absorb liquids and easy to clean ● Long life span: 3+ years ● Full water and dust protection ● Resistant to most oils and acids ● Suitable for intelligent logistics turnover ● Efficient! Pack, stack, ship, fold, return - repeat! ● Thermal insulation ● No deformation ● Non-toxic ● Odorless ● High toughness ● Moisture resistant ● Bend resistant ● Flame retardant ● UV radiation resistant ● Dirt resistant ● Corrosion resistant ● High impact resistant ● Chemical resistant ● Weather resistant ● Stand wear and tear ● Anti-aging ● Rot resistant ● Pest resistant ● Fungus resistant ● Break resistant ● Easily cleaned ● Easy to handle |

Accessories |

1 HDPE lid(Closed base and slides with drop door and lid) 1 PP sleeve 1 HDPE pallet 2 Belt handles 4 Belt locks 1 Label holder 2 Velcros 1 Loading door |

Application |

logistics, packaging, storage, turn over |

Packaging |

Fold and Wrap |

Place of Origin |

China |

FOB port |

Qingdao |

OTHER PALLET & LID SIZE

Blow Molding Type

Model |

Pallet Outer Diameter |

Pallet Inner Diameter |

Pallet Weight |

Lid Weight |

STACKING LAYER |

LOADING WEIGHT |

BM8060 |

800*600 |

740*540 |

7kg |

5kg |

1+2 |

300KGS |

BM1110 |

1100*1000 |

1050*950 |

10kg |

7.5kg |

1+2 |

300KGS |

BM1111 |

1100*1100 |

1055*1055 |

10kg |

8kg |

1+2 |

300KGS |

BM1198 |

1150*985 |

1100*935 |

10kg |

9kg |

1+2 |

300KGS |

BM1515 |

1150*1150 |

1105*1105 |

10.5kg |

8.5kg |

1+2 |

300KGS |

BM1280 |

1200*800 |

1140*740 |

10kg |

9kg |

1+2 |

300KGS |

BM1210 |

1200*1000 |

1140*940 |

11kg |

10kg |

1+2 |

300KGS |

BM1211 |

1220*1150 |

1170*1105 |

11kg |

9kg |

1+2 |

300KGS |

BM1210-3 |

1230*1030 |

1170*970 |

11.5kg |

8.5kg |

1+2 |

300KGS |

BM1311 |

1350*1140 |

1290*1080 |

14kg |

12kg |

1+2 |

300KGS |

BM1411 |

1470*1140 |

1410*1080 |

15kg |

13kg |

1+2 |

300KGS |

BM1611 |

1600*1140 |

1540*1085 |

20kg |

13kg |

1+2 |

300KGS |

BM1811 |

1840×1130 |

1540*1080 |

23kg |

12kg |

1+2 |

300KGS |

BM2011 |

2070*1150 |

2035*1115 |

30kg |

16kg |

1+2 |

300KGS |

Injection Type

Model |

Pallet Outer Size |

Pallet Inner Size |

FOLDING HEIGHT |

LOADING WEIGHT |

STACKING LAYERS |

REMARK |

ZS1210 |

1200*1000 |

1130*930 |

240 |

500 |

5 |

9 FEET/3 RUNNERS |

ZS1280 |

1200*800 |

1130*730 |

240 |

500 |

5 |

9 FEET/3 RUNNERS |

ZS1198 |

1140*980 |

1070*910 |

240 |

500 |

5 |

9 FEET/3 RUNNERS |

ZS1111 |

1140*1140 |

1070*1070 |

240 |

500 |

5 |

9 FEET/3 RUNNERS |

1.Lashing Belts and handle belts can be added | ||||||

2. 9 feets/3 runners are for options. | ||||||

3. Steel Tube can be added in pallet and lid for higher loading weight. | ||||||