Transform Your Supply Chain Economics with Smart Container Solutions

The logistics landscape is evolving rapidly, and forward-thinking suppliers are discovering the game-changing potential of collapsible bulk containers. These innovative storage and transport solutions are revolutionizing how businesses handle return freight costs, offering a compelling blend of efficiency, sustainability, and bottom-line benefits. As transportation expenses continue to climb, the ability to significantly reduce return shipping costs has become a critical competitive advantage.

The traditional rigid container model has long been a source of unnecessary expenses and logistical headaches. Empty containers returning to their point of origin consume valuable cargo space and inflate transportation costs. However, collapsible bulk containers are changing this paradigm by providing a practical solution that addresses these fundamental challenges while delivering additional operational benefits.

The Economic Impact of Container Return Logistics

Understanding Return Freight Cost Structures

Return freight represents a substantial portion of overall logistics expenses, often accounting for 20-30% of total shipping costs. Traditional rigid containers create a constant cycle of expenses, as they maintain their full volume whether empty or full. This inefficiency translates to higher fuel consumption, increased labor costs, and reduced vehicle utilization rates. When suppliers implement collapsible bulk containers, they can typically reduce return shipping volumes by up to 75%, creating immediate and substantial cost savings.

The cost implications extend beyond direct shipping expenses. Storage costs at distribution centers and warehouses also increase when managing rigid containers. These space requirements impact facility overhead and can limit operational flexibility. By adopting collapsible solutions, companies can optimize their storage footprint and better manage seasonal fluctuations in container demand.

Environmental and Operational Benefits

The environmental advantages of collapsible bulk containers align perfectly with modern sustainability initiatives. By reducing the number of return trips required, companies can significantly decrease their carbon footprint. This reduction in environmental impact often translates to tangible benefits, including compliance with environmental regulations and enhanced corporate social responsibility profiles.

Operational efficiency gains become apparent through improved handling times and reduced labor requirements. Workers can quickly collapse and stack empty containers, streamlining warehouse operations and maximizing available space. These improvements in workflow efficiency contribute to overall cost reduction and enhanced productivity.

Design Features That Drive Cost Savings

Structural Innovation and Material Science

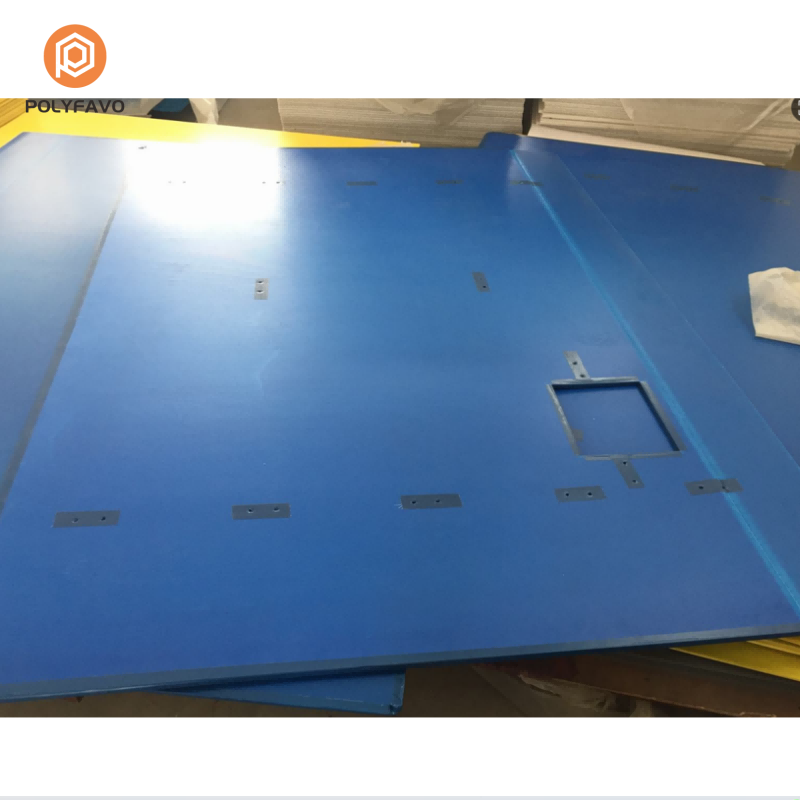

Modern collapsible bulk containers incorporate advanced engineering principles that ensure durability while maintaining their collapsible functionality. High-grade polymers and reinforced construction techniques allow these containers to withstand heavy loads and repeated use cycles without compromising their ability to fold down when empty. This balance between strength and flexibility is crucial for long-term cost effectiveness.

The latest designs feature optimized folding mechanisms that reduce the time and effort required for container manipulation. Quick-release systems and ergonomic handling points enable workers to collapse and deploy containers efficiently, minimizing downtime and reducing the risk of handling-related injuries.

Space Optimization Technologies

Advanced collapsible bulk containers are designed with precise ratios that maximize space utilization in both expanded and collapsed states. When collapsed, these containers typically achieve a 4:1 or 5:1 reduction ratio, meaning four or five collapsed containers can occupy the space of one expanded unit. This dramatic space savings directly translates to reduced transportation costs and more efficient warehouse utilization.

Innovative stacking features ensure stable loads in both configurations, while integrated tracking systems help managers monitor container locations and optimize return logistics. These technological advancements contribute to a more streamlined and cost-effective supply chain operation.

Implementation Strategies for Maximum Returns

Planning the Transition Process

Successfully implementing collapsible bulk containers requires careful planning and a phased approach. Begin by analyzing current shipping patterns and identifying routes where these containers will provide the greatest return on investment. Consider factors such as distance, frequency of shipments, and current return freight costs to prioritize implementation areas.

Develop a comprehensive training program for staff at all levels, ensuring proper handling procedures are understood and followed. This investment in training helps maximize container lifespan and maintain the expected cost savings over time. Create clear protocols for inspection, maintenance, and replacement to protect your investment in these valuable assets.

Measuring and Optimizing Performance

Establish key performance indicators (KPIs) to track the impact of collapsible bulk containers on your operations. Monitor metrics such as return freight costs, handling time, storage space utilization, and container durability. Regular analysis of these metrics helps identify opportunities for further optimization and ensures the continued effectiveness of your container strategy.

Use data analytics to fine-tune your container fleet size and distribution patterns. This information-driven approach helps maintain optimal container availability while minimizing excess inventory. Regular reviews of performance data support continuous improvement initiatives and help justify further investments in collapsible container solutions.

Frequently Asked Questions

What is the typical return on investment period for collapsible bulk containers?

Most companies experience a return on investment within 6-12 months of implementing collapsible bulk containers, depending on their shipping volumes and current freight costs. The combination of reduced transportation expenses, lower storage costs, and improved operational efficiency contributes to this rapid payback period.

How do collapsible bulk containers compare to traditional containers in terms of durability?

Modern collapsible bulk containers are engineered to match or exceed the durability of traditional rigid containers. With proper maintenance and handling, they typically last for hundreds of use cycles, providing reliable service for 5-7 years or more in normal operating conditions.

Can collapsible bulk containers handle temperature-sensitive products?

Yes, many collapsible bulk containers are available with insulation options and can be used for temperature-sensitive products. Specialized designs incorporate thermal barriers and can maintain product integrity across a wide range of environmental conditions while still providing the space-saving benefits of collapsibility.